- Top 10 World’s Largest Planters / Air Hoe Drills

- John Deere DB120 (120 ft / 37 m, 30 in)

- Case IH 2160 (90 ft / 28 m, 30 in)

- John Deere P690 (90 ft / 28 m, 12 in)

- Bourgault 5810-72 (73 ft , 22.4 m, 12 in)

- New Holland P2075 (70 ft / 22 m, 12 in)

- Kinze 5900 (61 ft / 18,9 m, 30 in)

- Massey Ferguson VF2430 (60 ft / 18.5 m, 30 in)

- Great Plains PL5905 (60 ft / 18.5 m, 30 in)

- Fendt Momentum 24 (55 ft / 16.8 m, 30 in)

- Vaderstad Tempo L 8-32 Central Fill (40 ft / 12.1 m, 15 in)

- PROs of Largest Planters

- CONs of Largest Planters

- Difference Between Planters and Air Hoe Drills

In the realm of contemporary agriculture, the imperative of optimizing efficiency and productivity reigns supreme. As agriculturalists endeavor to satisfy the escalating demands of global food production, the utilization of state-of-the-art machinery assumes heightened significance. Among these pioneering implements are the world’s largest planters, which are fundamentally reshaping the methodology of crop sowing across expansive farmlands.

These planters represent some of the largest and most advanced agricultural equipment available, designed to cover vast areas efficiently while ensuring precise planting accuracy.

Top 10 World’s Largest Planters / Air Hoe Drills

The amount of seed the seeder can hold determines the time between refills and the area it can cover before needing to be replenished. The distance between rows determines plant density and influences crop yield and weed control. Different crops require specific row spacing for optimal growth. The ability to adjust seed placement depth ensures proper seed-to-soil contact and germination rates, especially in varying soil conditions. The metering system regulates the flow of seed, ensuring consistent seed placement and accurate seeding rates across the field.

| Planter / Air Drill | Toolbar Width | Row Spacing | Seed Capacity |

|---|---|---|---|

| John Deere DB120 | 120 ft (37 m) | 30 in. | 125 bu (4,405 L) |

| Case IH 2160 | 90 ft (28 m) | 30 in. | 120 bu (4,229 L) |

| John Deere P690 | 90 ft (28 m) | 12 in. | 850 bu (29,953 L) with JD C850T Air Cart |

| Bourgault 5810-72 | 73 ft (22.4 m) | 12 in. | 1,300 Bu (45,810 L) with Bourgault 91300 Air Cart |

| New Holland P2075 | 70 ft (22 m) | 12 in. | 580 Bu (20,439 L) with Flexi-Coil P4580 Air Cart |

| Kinze 5900 | 61 ft (18.9 m) | 30 in. | 120 bu (4,229 L) |

| Massey Ferguson VF2430 | 60 ft (18.5 m) | 30 in. | 90 bu (3,172 L) |

| Great Plains PL5905 60′ Bulk-Fill | 60 ft (18.5 m) | 30 in. | 164 bu (5,779 L) |

| Fendt Momentum 24 | 55 ft (16.8 m) | 30 in. | 130 bu (4,581 L) |

| Väderstad Tempo L 8-32 Central Fill | 40 ft (12.1 m) | 15 in. | 85 bu (2,995 L) |

A seeder with effective ground-following capabilities maintains consistent seed placement, even on uneven terrain, ensuring uniform crop emergence. Some seeders include fertilizer application capabilities, allowing for simultaneous seeding and fertilization, which can improve crop yield and efficiency. The width of the seeder affects the amount of land it can cover in a single pass, while considerations for transportability include folding mechanisms for easy transport between fields and storage.

John Deere DB120 (120 ft / 37 m, 30 in)

The John Deere DB120 Planter stands as a pinnacle of precision and efficiency in modern agriculture. With its impressive 120 ft. (36.58 m) toolbar and 48 rows spaced at 30 in. (762 mm), this planter offers unparalleled productivity and accuracy in seed placement. Equipped with the advanced mini-hopper MaxEmerge™ 5 row unit, the DB120 ensures optimal seed delivery and distribution, contributing to uniform crop emergence and higher yields.

Its innovative design and engineering make it a reliable choice for farmers seeking maximum efficiency in their planting operations. To operate the DB120 effectively, a minimum of 276 kW (370 hp) tractor with Category 5 drawbar and five hydraulic SCVs plus power beyond is required. This underscores the planter’s robust construction and the power needed to handle its large-scale seeding capabilities.

Overall, the John Deere DB120 Planter represents a cutting-edge solution for modern agricultural needs, offering unmatched precision, efficiency, and performance to farmers worldwide.

Case IH 2160 (90 ft / 28 m, 30 in)

The Case IH 2160 Planter is a versatile and high-performance seeding solution tailored to meet the diverse needs of modern agriculture. With various configurations available, including 24-row, 32-row, 36-row, and 47-row split-row options, farmers can choose the setup that best suits their specific requirements. Featuring row spacing options of 20-, 22-, 30-inch, or 15-inch, the Case IH 2160 offers flexibility to accommodate different crop types and planting practices. Whether on wheeled or tracked carriers, this planter delivers consistent and precise seed placement across the field. The planter’s toolbars range from 60 to 90 feet, ensuring efficient coverage of large acreages. Depending on the planter size, desired speed, and terrain conditions, it requires between 380 to 620 engine horsepower to operate effectively, underscoring its robust construction and capability to handle varying field conditions.

Overall, the Case IH 2160 Planter combines versatility, precision, and power to provide farmers with a reliable solution for their planting needs, helping them achieve optimal yields and maximize efficiency in their operations.

John Deere P690 (90 ft / 28 m, 12 in)

The John Deere P690 Precision Air Hoe Drill, when paired with the C850T Air Cart and John Deere 9R Tractors, offers a comprehensive solution for modern seeding operations. With the integration of the John Deere Operations Center™ application, users gain invaluable insights into their seeding activities, enabling them to make informed decisions to maximize profitability. One of the standout features of the P690 Precision Air Hoe Drill is its user-friendly interface, which simplifies operation and data management. Wireless data transfer capabilities further streamline the workflow, allowing operators to focus more on essential tasks in the field.

By leveraging advanced technology and precision seeding capabilities, the P690 ensures optimal seed placement and uniform crop emergence, ultimately contributing to higher yields and improved profitability. Additionally, the seamless compatibility with John Deere 9R Tractors enhances efficiency and performance across the entire seeding operation.

Overall, the John Deere P690 Precision Air Hoe Drill offers a powerful combination of precision, efficiency, and ease of use, empowering farmers to achieve superior results and gain a deeper understanding of their seeding operations for long-term success.

Bourgault 5810-72 (73 ft , 22.4 m, 12 in)

The Bourgault 5810-72 Air Hoe Drill is a high-performance seeding implement designed for efficient and precise seed placement in various agricultural applications. With a working width of 73 feet (22.4 meters), the Bourgault 5810-72 covers a substantial amount of ground in each pass, maximizing productivity and reducing time spent in the field. The wide coverage makes it suitable for large-scale farming operations. The drill features a row spacing of 12 inches, allowing for optimal seed placement and uniform crop emergence. Additionally, it offers precise depth control, ensuring that seeds are planted at the desired depth for optimal germination and crop establishment. The Bourgault 5810-72 is versatile and can be used for various seeding tasks, including direct seeding into stubble, minimum tillage, and no-till operations. It can handle a wide range of crop types, including cereals, oilseeds, pulses, and cover crops. The drill’s precise seed metering and placement capabilities contribute to optimal seed-to-soil contact and germination, resulting in uniform crop emergence and improved yield potential. This precision seeding technology enhances overall crop uniformity and stand establishment.

Overall, the Bourgault 5810-72 Air Hoe Drill offers exceptional performance, versatility, and reliability, making it an ideal choice for modern farming operations looking to maximize efficiency and productivity in seed placement.

New Holland P2075 (70 ft / 22 m, 12 in)

One of the key features of the New Holland P2075 Air Hoe Drill is its ability to precisely place seeds at a consistent depth, while simultaneously depositing fertilizer in close proximity to the seeds for enhanced nutrient uptake by the roots. The drill employs side-banding techniques, positioning fertilizer 1-7/8 inches to the side and 7/8 inch below the seed, optimizing the seed/fertilizer separation for crop safety and minimizing the need for root exploration. Moreover, the row-unit frame of the P2075 is engineered to be shorter than that of other drills, resulting in more accurate and consistent seed depth. Each individual row unit can travel more than 15 inches, with 8 inches up and 7 inches down, allowing for exceptional ground following capability and ensuring uniform seed placement across the entire field.

In contrast to competitor row units lacking parallel link technology, which may result in inaccuracies in seed and fertilizer depth due to limited ground following ability, the New Holland P2075 stands out for its precision and reliability, making it a top choice for farmers seeking superior seeding performance and maximum crop yields.

Kinze 5900 (61 ft / 18,9 m, 30 in)

Equipped with the 5000 Series row unit, Blue Drive electric drive, and the True Rate vacuum electric meter, the Kinze 5900 Planter delivers fully integrated electric planting capabilities, ensuring precise seed placement and optimal seed-to-soil contact for improved germination and crop yield. With the True Depth hydraulic down force system, the Kinze 5900 Planter maintains consistent seed depth across varying soil conditions, ensuring uniform seed placement and promoting optimal seedling emergence. Featuring air-adjustable closing wheels controlled by the Blue Vantage display, the 5900 Planter enables precise adjustment for optimal seed-to-soil contact, enhancing seedling establishment and promoting uniform crop emergence. The planter’s high clearance frame with 3-section front fold and 42 degrees of wing flex ensures smooth navigation over rolling terrain, allowing operators to cover more ground efficiently and effectively.

For added convenience, the 5900 Planter offers a time-saving liquid fertilizer system with onboard capacity ranging from 400 to 750 gallons, along with optional factory plumbing for nurse or saddle tanks, allowing for precise row-by-row fertilizer application at rates ranging from 2 to 25 gallons per acre.

Massey Ferguson VF2430 (60 ft / 18.5 m, 30 in)

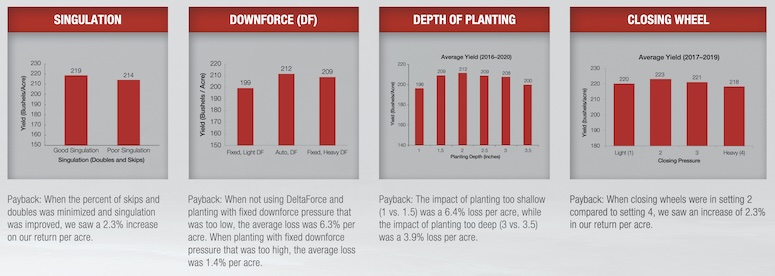

Equipped with cutting-edge features like vSet2® meters, vDrive®, and DeltaForce, the Massey Ferguson VF2430 Planter enables precise seed singulation and placement right from the factory. Moreover, it provides the flexibility to incorporate aftermarket components through local premier Precision Planting dealers. Featuring individual row unit hoppers or a central fill system with capacities of up to 90 bushels, as well as options for liquid fertilizer ranging from 300 to 750 gallons, the VF2430 Planter offers versatility to suit varying needs and field conditions. Additionally, dry fertilizer and insecticide options further enhance its functionality.

Extensive field studies have quantified the impact of poor seed singulation, optimized planting depth, and evaluated the influence of closing wheel aggressiveness across multiple locations and growing environments. These studies underscore the VF2430 Planter’s commitment to delivering superior performance and maximizing crop yields.

Overall, the Massey Ferguson VF2430 Planter sets a new standard for precision, efficiency, and yield potential, making it an invaluable tool for modern farming operations striving for optimal productivity and profitability.

Great Plains PL5905 (60 ft / 18.5 m, 30 in)

The Great Plains PL5905 sets a new standard in bulk-fill planters, catering to the demands of large-acreage farming. Boasting a 60 ft width and capable of transporting under 16 ft, it maximizes in-field efficiency while holding an impressive 164 bu. of seed onboard. Offering both 15″ and 30″ row spacings, it accommodates a wide range of crops, from traditional soybeans and corn to alternative seeds like hemp and canola.

Crafted for durability and reliability, the PL5905 features robust 05 Series row units with enhanced pivot bushings and a sturdy parallel arm system. Equipped with Air-Pro® meters for precise seed singulation and IRC electric drive for variable-rate seeding, it ensures optimal seed placement for every crop. Additionally, advanced options such as the AccuShot™ in-row fertilizer system and Ag Leader’s SureForce™ hydraulic downforce technology further elevate its performance, ensuring seeds get the perfect start they need. Ideal for large operations, the PL5905 combines practical technology with unmatched productivity, making it a top choice for modern farming ventures.

Fendt Momentum 24 (55 ft / 16.8 m, 30 in)

The Fendt Momentum 24 sets a new standard in precision planting, offering unparalleled performance and versatility to meet the demands of modern agriculture. With a robust design and innovative features, this 55-ft planter is engineered to maximize efficiency and productivity in the field. Equipped with LoadLogic weight management, the Momentum 24 ensures optimal weight distribution for enhanced stability and performance. With three distinct modes – Load Balance, Weight Centralization, and Floating Position – it offers flexibility to adapt to varying field conditions and operational requirements.

With features like curve compensation, precision seed placement, and fertilizer application, the Fendt Momentum 24 delivers superior results while minimizing yield losses. Its modular row unit system allows for customization to suit specific conditions, ensuring optimal performance in any situation. Driven by electric row units and controlled via ISOBUS technology, the Momentum 24 offers intuitive operation and precise control over key functions. From seed and fertilizer monitoring to machine folding and unfolding, operators can easily manage operations from the cab for maximum efficiency.

In summary, the Fendt Momentum 24 is a game-changer in precision planting, offering advanced technology, unmatched performance, and exceptional reliability to meet the evolving needs of modern agriculture.

Vaderstad Tempo L 8-32 Central Fill (40 ft / 12.1 m, 15 in)

The Väderstad Tempo L 8-32 Central Fill redefines high-speed planting with its cutting-edge technology and exceptional precision. This next-generation planter operates at double the speed of traditional models, delivering uniform emergence and optimal crop starts across varied tillage conditions. At the heart of the Tempo L is its innovative Central Seed Fill system, which eliminates the need for a central motor by empowering each row unit with its seed regulation mechanism. This ensures precise seed metering through the PowerShoot system, guaranteeing accurate seed placement and spacing.

With an 85-bushel seed hopper (expandable to 204.3 bushels for seed and fertilizer models), the Tempo L provides ample capacity for uninterrupted planting. Its advanced feeding system efficiently distributes seeds to individual row units, optimizing seed delivery and minimizing downtime. The planter’s telescoping wheel axle and hydraulic wing pressure system enhance field adaptability and ensure uniform seed placement, even in challenging terrain. With the ability to adjust row spacing and wheel alignment from the cab, the Tempo L planter offers unparalleled versatility and ease of operation. Overall, the Väderstad Tempo L 8-32 Central Fill sets a new standard in high-speed planting, combining cutting-edge technology with practical design to maximize productivity and crop performance.

PROs of Largest Planters

- Increased Efficiency: Large planters cover more ground in less time, allowing farmers to plant extensive areas quickly and efficiently.

- Enhanced Productivity: With the ability to plant more seeds in a single pass, larger planters contribute to higher overall productivity and yield per acre.

- Precision Planting: Many large planters are equipped with advanced GPS and precision planting technology, ensuring accurate seed placement and optimal spacing for optimal crop growth.

- Reduced Labor Costs: By automating various planting tasks and covering more ground with each pass, large planters help reduce the need for manual labor, leading to cost savings for farmers.

- Versatility: Some large planters offer modular designs or customizable features, allowing farmers to adapt them to different crops, field conditions, and farming practices.

CONs of Largest Planters

- High Initial Investment: Large planters typically come with a significant upfront cost, which can be a barrier for smaller or less capitalized farms.

- Maintenance Requirements: Maintaining and servicing large planters can be complex and costly, requiring specialized equipment and technical expertise.

- Soil Compaction: The weight and size of large planters can contribute to soil compaction, which may affect soil health and crop yield over time.

- Limited Maneuverability: Due to their size, large planters may have limited maneuverability, making it challenging to navigate around obstacles or in irregularly shaped fields.

- Dependency on Weather Conditions: Large planters are often more sensitive to adverse weather conditions such as rain or soil moisture levels, which can affect their performance and efficiency.

While large planters offer numerous benefits in terms of efficiency and productivity, farmers must carefully weigh these advantages against potential challenges and consider their specific operational needs and constraints before investing in these farm implements.

Difference Between Planters and Air Hoe Drills

Planters and air hoe drills are both agricultural implements used for sowing seeds, but they have distinct differences in terms of design, function, and application:

- Function:

- Planter: Planters are designed specifically for precise planting of seeds in rows with consistent spacing and depth. They typically include mechanisms for opening furrows, placing seeds at the desired depth, and covering them with soil. Planters are commonly used for row crops like corn, soybeans, cotton, and vegetables.

- Air Hoe Drill: Air hoe drills, also known as air seeders or pneumatic drills, are used for sowing seeds in tilled or untilled soil. They use pressurized air to deliver seeds and often fertilizer through tubes to individual openers or coulters, which create furrows and deposit the seeds. Air hoe drills are suitable for various crops, including cereals, oilseeds, pulses, and cover crops.

- Seed Placement:

- Planter: Planters place seeds in rows with precise spacing and depth control. They typically have seed meters and depth gauging systems to ensure accurate seed placement.

- Air Hoe Drill: Air hoe drills distribute seeds evenly across the width of the implement, often using metering systems to regulate seed flow. Seed depth can vary depending on soil conditions and the design of the drill’s openers.

- Seed Metering:

- Planter: Planters use seed meters to measure and dispense seeds at a predetermined rate. These meters are calibrated to achieve the desired seeding rate per unit area.

- Air Hoe Drill: Air hoe drills also use metering systems to control the rate of seed flow. They may employ different metering mechanisms, such as fluted rollers or augers, to accurately deliver seeds to the openers.

- Fertilizer Application:

- Planter: Some planters have integrated fertilizer systems that allow simultaneous planting and fertilizing. Fertilizer is often placed in bands near the seed to provide essential nutrients during germination and early growth.

- Air Hoe Drill: Air hoe drills can accommodate fertilizer application in addition to seed sowing. They may have separate compartments for seed and fertilizer, allowing for independent control of seeding rates and fertilizer placement.

- Versatility:

- Planter: Planters are primarily used for planting row crops and may have limited flexibility in terms of seed spacing and crop types.

- Air Hoe Drill: Air hoe drills offer greater versatility and can be used for various seeding tasks, including direct seeding into stubble, cover cropping, intercropping, and precision seeding of multiple crop types.

In summary, planters are specialized implements designed for precise row planting of seeds, while air hoe drills are versatile seeding tools capable of handling various seeding methods and crop types using pneumatic seed delivery systems.

Is the John Deere DB120 the largest row crop planter?

Yes, this is currently the largest row crop planter on the market not only in the USA, but also in the world!

What about the Zells 214 ft air seeder? Isn’t this the largest seeder in the world?

Yes, the Zells 214ft Planting Rig is considered the largest air seeder. This massive planter is used for large-scale agricultural operations and has gained recognition for its impressive size and capacity, enabling efficient planting over extensive areas. The Zells family has utilized this rig for planting crops such as wheat, demonstrating its capability to navigate and operate effectively in various field conditions. BUT!!! The Zells 214ft Planting Rig, which holds the title of the largest air seeder in the world, IS NOT PRODUCED COMMERCIALLY. It was custom-built by Wayne Zell and his family in Australia, utilizing a frame produced by Multi Farming Systems, which also offers commercially available seeders up to 160 feet in length