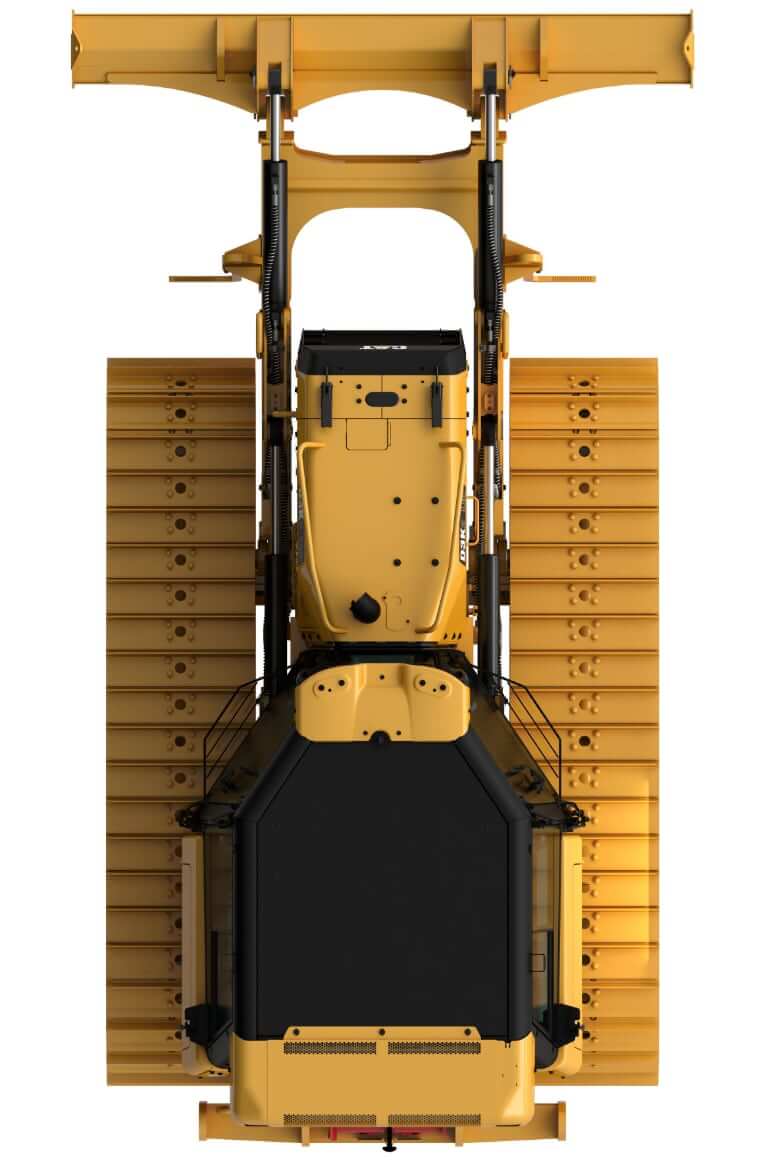

Dimensions

| Overall Length with Blade | 190.2 in (4830 mm) |

| Width of Dozer with Blade | 94.5 in (2400 mm) |

| Width of Dozer without Blade | 74.8 in (1900 mm) |

| Dozer Height | 108.8 in (2763 mm) |

Dozer Blade

| Blade Capacity | 2.07 yd3 (1.58 m3) |

| Blade Height | 34.4 in (875 mm) |

| Blade Width | 7.88 ft in (2400 mm) |

| Blade Lift Height | 62.2 in (1580 mm) |

| Blade Tilt – Front | 38 degrees |

| Blade Tilt – Rear | 30 degrees |

| Digging Depth | 23 in (588 mm) |

| Description | Two-Way dozer designed for use in shiphold to move various bulk material. Inside mounted c-frame provides lift height suitable for pulling material off ship walls |

| Blade Control | Blade pitches hydraulically forward or rearward for versatile operation |

Undercarriage

| Track Gauge | 4.91 ft in (1495 mm) |

| Shoe Width – Standard | 15.9 in (405 mm) |

| Joystick Control | Intuitive steering, direction and speed control Power turn provides optimum maneuverability |

| LGP configuration | Available for material requiring additional machine floatation |

| Transmission Type | Hydrostatic Transmission |

| Maximum Travel Speed – Forward | 5.6 mph (9 km/h) |

| Maximum Travel Speed – Reverse | 6.2 mph (10 km/h) |

Operating Specs

| Operating Weight | 18775 lb (8516 kg) |

| Voltage | 12 V |

| Alternator | 120 amps |

| Battery | 2x 12 V, CCA 750 (heavy duty, maintenance free) |

*Specs are for CAT D3K2 dozer equipped with blade, cab ROPS, back-up alarm, operator, coolant, lubricants and full fuel tank.

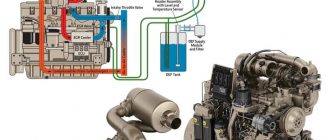

Engine Details

| Number Of Cylinders | 4 |

| Engine Make | Caterpillar |

| Engine Model | Cat C4.4 ACERT |

| Net Power | 80 hp (60 kw) |

| Power Measured @ | 2200 rpm |

| Displacement | 268.5 cu in (4.4 L) |

| Bore | 4.13 in (105 mm) |

| Stroke | 5.00 in (127 mm) |

| Air Filter | Engine air precleaner (centrifugal) located under hood for longer air filter life |

| Emission Standards | U.S. EPA Tier 4 Final, EU Stage IV |

Operator Environment

| ROPS/FOPS | Enclosed Roll-Over Protective Structure (EROPS) 3471:2008 + FOPS ISO 3449:2005 Level II |

| Sound Level in Cab | 79 dB(A) ISO 6396:2008 / 79 dB(A) SAE J1166 FEB2008 |

| HVAC | Standard air conditioning with cab option |

| Operator Sear | Fully adjustable air suspension seat + Seat mounted joystick controls |

Hydraulic System

| Hydraulic Pump Flow | 17.7 gal/min (68 L/min) |

| Relief Valve Settings | 2988 psi (20600 kPa) |

| Hydraulic System Test | Grouped pressure taps for quick testing and troubleshooting of the hydraulic system |

| Access | Easy ground level access to hydraulic filters located in the left rear service compartment |

Service Refill Capacities

| Fuel Tank Capacity | 51.5 gal (195 L) |

| Engine Oil Capacity (with Filter) | 2.9 gal (11 L) |

| Cooling System Capacity | 5.92 gal (22.4 L) |

| Hydraulic System Capacity | 15.7 gal (59.5 L) |

| Final Drives (Each) | 2.6 gal (10 L) |

The CAT D3K2 Shiphold/Port Handling Dozer is specifically designed for efficient operation in shiphold and port environments, providing versatility, safety, and precision. The small footprint and excellent maneuverability make it ideal for working in tight shipholds or port areas. Low ground pressure ensures minimal damage to surfaces, which is crucial in ports and storage facilities. Equipped with blades designed for precise material handling and grading, ensuring efficient operations such as stacking, leveling, or clearing debris. Built to withstand abrasive materials like coal, grain, or aggregates, commonly found in shipholds and ports. Corrosion-resistant components and protective guarding enhance machine durability in harsh conditions.

The reliable CAT engine delivers excellent fuel efficiency while maintaining high performance, even when handling heavy loads. Its compact size allows for easier transport between job sites, especially in urban or port settings. Optional GPS or grade control systems improve accuracy and productivity. Monitoring systems allow for real-time performance insights and maintenance alerts. Centralized service points and robust design reduce downtime, ensuring higher availability for continuous operations. This makes the CAT D3K2 Shiphold/Port Handling Dozer an optimal choice for port and shiphold tasks where reliability, maneuverability, and efficiency are paramount.