Modern tractors, such as those from New Holland and Case IH, come equipped with advanced front suspension systems to provide operators with a smoother and more comfortable ride. However, like any complex machinery, these systems can encounter issues that need prompt diagnosis and resolution. Front Suspension Error Codes, or Diagnostic Trouble Codes (DTCs), are invaluable tools for tractor mechanics in addressing these problems efficiently.

Front Suspension Error Codes are numerical identifiers generated by the tractor’s front suspension system when it detects a malfunction or problem. These codes serve as diagnostic indicators, enabling mechanics to swiftly identify and rectify issues within the suspension system.

Front Suspension Error Codes play a pivotal role in streamlining the troubleshooting process. When a problem arises within the front suspension system, these codes provide an initial point for identifying the issue, ultimately reducing downtime during critical farming operations.

New Holland & Case IH Front Suspension Errors

Here is the table with the error / fault code numbers and descriptions for the front suspension:

| Error Code | Error Description |

|---|---|

| 10001 | Front suspension pump – not tank valve solenoid open or shorted to ground |

| 10002 | Front suspension rod side valve solenoid open or shorted to ground |

| 10003 | Front suspension piston side valve solenoid is open or shorted to ground |

| 10004 | Front suspension position sensor out of range High error |

| 10005 | Front suspension position sensor out of range Low error |

| 10006 | Front suspension does not cause an error |

| 10007 | Front suspension will not lower error |

| 10008 | Front suspension piston high pressure sensor range error |

| 10009 | Front Suspension piston pressure sensor Low Range Error |

| 10010 | Front Suspension Bar High-Pressure Sensor Range Error |

| 10011 | Front Suspension Rod Pressure Sensor Low Range Error |

| 10012 | Front Suspension Rod side pressure does not cause an error |

| 10013 | Pressure from the front suspension piston will not raise the error |

| 10014 | Front suspension not calibrated error |

| 10015 | The front suspension lock solenoid valve has an open or short to ground. |

| 10016 | Front Suspension enable switch error 10016 |

| 10017 | Front Suspension enable switch NA error 10017 |

| 10018 | Front Suspension Pump Not Tank Overcurrent Solenoid |

| 10019 | Front Suspension Link Side Over Current Solenoid |

| 10020 | Overcurrent front suspension piston solenoid |

| 10021 | Front Suspension Lock Electromagnetic Over Current |

| 10022 | Low voltage front suspension suppl 12VM (probably blown fuse) |

| 10023 | 12VF3 Supply voltage low (probably blown fuse) |

| 10024 | 12VF1 Supply voltage low (probably blown fuse) |

Front Suspended Axle Error Codes (GCM1 or XCM)

| Error Code | Error Description |

|---|---|

| L01 | Lockout Valve Raising Solenoid Not Working |

| L02 | Raising Solenoid Not Working |

| L03 | Lowering Solenoid Not Working |

| L04 | Front Axle Potentiometer Threshold Is Higher Than The Set Limit |

| L05 | Front Axle Potentiometer Threshold Is Lower Than The Set Limit |

| L06 | The Suspension Is Not Calibrated |

| L07 | Front Axle Weight Has Been Reduced But The Suspension Is Unable To Reset Nominal Height |

| L08 | Front Axle Weight Has Been Increased But The Suspension Is Unable To Reset Nominal Height |

| L09 | Lockout Valve Lower Solenoid Not Working |

Understanding Front Suspension Error Codes is paramount for maintaining the ride quality, safety, and efficiency of your New Holland or Case IH tractor’s front suspension system. By implementing regular maintenance practices, providing operator training, and seeking professional help when necessary, you can ensure that your tractor’s front suspension operates optimally, contributing to a comfortable and productive farming experience.

Upon encountering an error code, it is crucial to consult the tractor’s manual or seek the expertise of a certified tractor mechanic. They will utilize specialized diagnostic equipment to pinpoint the specific problem within the front suspension system. Regular inspections of front suspension components, including sensors, air compressors, and control modules, can detect issues early, averting potential breakdowns.

Tractor operators should receive training to recognize error code notifications related to the front suspension system. Prompt reporting of error codes to maintenance personnel can prevent more extensive problems from developing. Incorrect operation, such as overloading the tractor or subjecting it to excessive shocks, can trigger error codes in the front suspension system. Operators must follow manufacturer guidelines for the proper use of the tractor and its suspension components.

If you encounter a front suspension error code that you are unsure how to address, or if the problem persists despite basic troubleshooting, it is advisable to seek assistance from a qualified tractor mechanic. They possess the expertise and tools necessary to diagnose and resolve complex front suspension system issues.

How Can I Prevent New Holland & Case IH Front Suspension Errors?

Preventing Front Suspension errors on New Holland and Case IH tractors involves a combination of regular maintenance, proper operation, and proactive troubleshooting. Here are some tips to help prevent Front Suspension errors:

- Regular Maintenance: Follow the manufacturer’s recommended maintenance schedule outlined in the tractor’s service manual. Regularly inspect and maintain the Front Suspension components, including checking for wear, lubricating as needed, and replacing any worn-out parts.

- Operate within Specifications: Operate the tractor within the specified load capacities and operational parameters outlined in the user manual. Avoid exceeding the limits of the Front Suspension system, as this can lead to stress and potential errors.

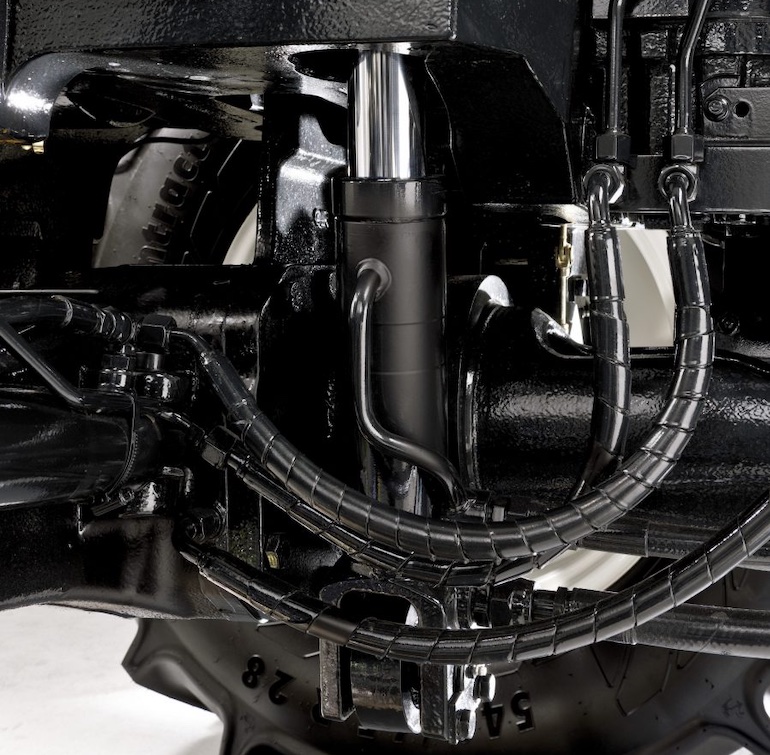

- Check Hydraulic Systems: If the Front Suspension system is hydraulic, regularly inspect the hydraulic components, including hoses, fittings, and cylinders. Address any leaks or damaged components promptly.

- Calibrate Sensors: If your tractor is equipped with sensors related to the Front Suspension system, ensure they are calibrated according to the manufacturer’s guidelines. Accurate sensor readings are crucial for proper system function.

- Monitor Warning Lights: Pay attention to warning lights or indicators on the tractor’s dashboard related to the Front Suspension system. If any warning lights illuminate, address the issue promptly rather than continuing to operate the tractor with potential problems.

- Protect from Environmental Factors: Shield the tractor from extreme weather conditions, especially when not in use. Moisture, excessive heat, and other environmental factors can contribute to Front Suspension system issues.

- Proper Shutdown Procedures: Follow proper shutdown procedures outlined in the manual. Avoid abrupt stops or shutting down the tractor without allowing the Front Suspension system to settle properly.

- Keep Software Updated: If your tractor’s Front Suspension system relies on software, keep it updated to the latest version provided by the manufacturer. Software updates may include improvements and bug fixes.

- Professional Inspections: Schedule regular inspections by certified technicians. Professionals can identify and address potential issues before they lead to errors.

- Operator Training: Ensure that tractor operators are trained on proper usage, maintenance, and troubleshooting procedures related to the Front Suspension system. Knowledgeable operators are more likely to detect and prevent issues.

By implementing these preventive measures, you can reduce the likelihood of Front Suspension errors on your Case IH and New Holland tractors. Regular maintenance, adherence to operational guidelines, and proactive attention to potential issues contribute to the overall reliability and performance of the Front Suspension system.

Can I Clear New Holland & Case IH Front Suspension Errors Myself?

Clearing Front Suspension errors on New Holland and Case IH tractors may be possible in some cases, but it’s crucial to approach this with caution. Suspension errors often indicate potential issues within the tractor’s systems, and clearing them without addressing the root cause could lead to persistent problems.

Here are some considerations if you are contemplating clearing Front Suspension errors yourself:

- Refer to the Manual: Consult the tractor’s service manual for information about Front Suspension errors, their meanings, and any recommended troubleshooting steps. The manual will provide specific guidance related to your tractor model.

- Address Underlying Issues: Before attempting to clear error codes, identify and address any underlying issues causing the errors. Clearing codes without resolving the problem may lead to ongoing malfunctions.

- Use Diagnostic Tools: Specialized diagnostic tools, often specific to the manufacturer, may be required to clear Front Suspension errors. If you have access to such tools, follow the manufacturer’s instructions for code clearing procedures.

- Disconnect Battery: Disconnecting the tractor’s battery for a short period may reset the electronic control systems and clear some errors. However, this method may not work for all models, and it’s essential to check the manual.

- Seek Professional Assistance: If you are unsure about how to clear Front Suspension errors or if you are unable to resolve the underlying issue, it’s advisable to seek assistance from a certified Case IH or New Holland mechanic or an authorized service center. They have the expertise to diagnose and address problems properly.

Clearing error codes without addressing the root cause may lead to ongoing issues. It’s crucial to follow the manufacturer’s guidelines, use appropriate diagnostic tools, and ensure that any underlying problems are resolved. If you lack the necessary tools or expertise, involving professionals is the safest and most effective approach when working on your tractor’s Front Suspension system. Always prioritize safety and adhere to manufacturer guidelines when performing maintenance or troubleshooting.

DTC Fault Code Lists of New Holland & Case IH Tractors:

- Armrest Errors

- ATC Error Codes

- Auxiliary Remote Valve Errors

- DCU Errors

- Engine Error Codes

- Front PTO Error Codes

- Hitch Error Codes

- Instrument Control Unit Errors

- INST Error Codes

- MFD/Diff List of Errors

- Multifunction Controller Errors

- Rear PTO Error Codes

- Transmission Error Codes

- FAQ for CNH Industrial DTCs

Can’t seem to find 18255 and 18256. What do these refer to?

New Holland / Case IH Error Code 18256 = Problem with armrest dispenser controls. Solution: Replace faulty valve controls

New Holland / Case IH Error Code 18255 (ACML) = EHR2 (Electro-Hydraulic Remote control system) Lever Position. Check EHR control unit