Kubota engines, known for their reliability and efficiency, utilize error codes to help diagnose and troubleshoot issues effectively. Whether you’re a seasoned mechanic or a Kubota engine owner looking to understand error codes better, this resource is designed to provide you with valuable insights. In this guide, you’ll find a curated list of Kubota engine error codes, along with their descriptions and potential causes. Understanding these error codes can empower you to identify problems promptly, leading to quicker resolutions and minimal downtime.

Explore our list of Kubota engine error codes to gain valuable knowledge and enhance your troubleshooting capabilities. Whether you’re maintaining agricultural equipment, construction machinery, or utility vehicles, having a grasp of these error codes can be invaluable in keeping your Kubota engine running smoothly. Please note that this list is for informational purposes only. For accurate diagnosis and repair of Kubota engine issues, always consult the manufacturer’s documentation or seek assistance from authorized Kubota service professionals.

Kubota Engine Error Codes (P 0016 – P 3001)

So, let’s embark on a journey through the world of Kubota Engine Error Codes, demystifying the language of your engine’s diagnostics and empowering you to keep your equipment in prime working condition.

| Kubota DTC Fault Code | P 0016 | P 0072 | P 0073 | |

|---|---|---|---|---|

| Name | Cam/Crank Sensors | Ambient Air Temperature | Ambient Air Temperature | |

| DTC Name | Crank and/or Cam Could Not Synchronize During Start | Intake air temp. built-in MAF sensor: Low | Intake air temp. built-in MAF sensor: High | |

| J1939 | SPN | 636 | 171 | 171 |

| FMI | 8 | 4 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • Mechanical misalignment between cam and crank | • Ground short circuit of sensor or harness | • Open circuit or +B short circuit of sensor or harness | |

| DTC Set Preconditions | • Engine Cranking or Running | • Battery voltage is normal | • Battery voltage is normal | |

| DTC Set Conditions | • Cranking revs without sysnc > 4.0 revs and RPM > 90 min-1 (rpm) | • Intake air temp. built-in MAF sensor voltage: 0.1 V or less | • Intake air temp. built-in MAF sensor voltage: 4.9 V or more | |

| Period for Judgment or Number of Occurrence for Judgment | • 2 sec | • 2.8 sec or more | • 2.8 sec or more | |

| System Action | • | • 25 deg. C (77 deg. F) [default value] | • 25 deg. C (77 deg. F) [default value] | |

| Engine Warning Light | ON | ON | ON | |

| Kubota DTC Fault Code | P 0087 | P 0088 | P 0089 | |

|---|---|---|---|---|

| Name | FP | FP | SCV | |

| DTC Name | Fuel pressure low | Fuel pressure high | SCV Stuck | |

| J1939 | SPN | 94 | 94 | 1347 |

| FMI | 1 | 0 | 7 | |

| MIL | ON | ON | ON | |

| Detected Item | • Fuel presure abnomality (Low side) | • Fuel presure abnomality (High side) | • SCV stuck at open position (Actual rail pressure continuously exceeds the command rail pressure) | |

| DTC Set Preconditions | • Engine Running | • Engine Running | • Supply pump is normal and pump calibration has been executed • Engine is operating • Injector is normal • Battery voltage is normal • Sensor supply voltage VCC# is normal • Rail pressure sensor is normal |

|

| DTC Set Conditions | • FP fault mode Gasoline only faults 0.0 sec

• run time wait for fuel pressure lowfaults 5.0 sec • FP pressure < 345 kPa [abs](3.52 kgf/cm2, 50.0 psia) |

• FP fault mode Gasoline only

• run time wait for fuel pressure highfaults 5.0 sec • FP pressure > 448 kPa [abs](4.57 kgf/cm2, 65.0 psia) |

• Discharge request of supply pump goes 0 mm3/stroke or less and the actual rail pressure is 10 MPa (100 kgf/cm2, 1400 psi) more than command pressure Above state continues for 26 seconds or more | |

| Period for Judgment or Number of Occurrence for Judgment | • 2 sec | • 2 sec | • One time or more | |

| System Action | • AL Disable KC

• Low Rev Limit |

• AL Disable KC

• Low Rev Limit |

• See Service Manual | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0090 | P 0091 | P 0092 | |

|---|---|---|---|---|

| Name | Open circuit of harness Open circuit of PCV coil | FP | FP | |

| DTC Name | Open circuit of harness or coil in PCV line | FP Low Voltage | FP High Voltage | |

| J1939 | SPN | 523612 | 94 | 94 |

| FMI | 5 | 4 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • Open circuit of harness Open circuit of PCV coil | • Sensor/wiring harness open/short to ground

• Sensor malfunction |

• Sensor/wiring harness short to power

• Sensor malfunction |

|

| DTC Set Preconditions | • Battery voltage is normal • During PCV driving • CPU is normal (VDIC2 is normal) |

• KeyON | • KeyON | |

| DTC Set Conditions | • Open circuit of harness or Open circuit of PCV coil | • FP voltage < 0.100 V | • FP voltage > 4.90 V | |

| Period for Judgment or Number of Occurrence for Judgment | 8 times or more | • 1 sec | • 5 sec | |

| System Action | • Output limitation: Approximately 50% of normal condition • Speed limitation (Accelerator limitation: 50%) EGR stop |

• AL Disable KC

• Low Rev Limit |

• AL Disable KC

• Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0093 | P 0107 | |

|---|---|---|---|

| Name | Fuel leak | MAP | |

| DTC Name | Fuel leak (in high pressured fuel system) | MAP Low Voltage | |

| J1939 | SPN | 1239 | 106 |

| FMI | 1 | 4 | |

| MIL | ON | ON | |

| Detected Item | • Fuel leak from high pressured fuel system (Fuel consumption is calculated from the difference of fuel pressure of before and after the injection, and the error will be detected when excess fuel consumption is found) | • Sensor/wiring harness open/short to ground

• Sensor malfunction |

|

| DTC Set Preconditions | • Battery voltage is normal • Sensor supply voltage VCC# is normal • Rail pressure sensor is normal • Supply pump (SCV) is normal • Injector and injector drive circuit are normal • NE signal is active [Engine is operating (700 rpm or more)] • No DTC of P0087, P0088, P0089 |

• Engine Cranking or Running | |

| DTC Set Conditions | • (a) the flow volume which is calculated from the difference of rail pressure (decrease). • (b) total volume of injection and leakage. • Fuel leak is judged with following conditions: – In case, engine speed is more than 1200 rpm: when the difference of (a) and (b) is 120 mm3/stroke or more, (a) is more than (b), and fuel leak is not from opening pressure limiter. – In case, engine speed is 1200 rpm or less: when the difference of (a) and (b) is 400 mm3/stroke or more, (a) is more than (b), and fuel leak is not from opening pressure limiter |

• MAP voltage < 0.050 V

• andTPS>5.0% • and RPM < 4000 min-1 (rpm) |

|

| Period for Judgment or Number of Occurrence for Judgment | • One time or more | • 1 sec | |

| System Action | • Stop ENG, See Service Manual | • AL Disable KC

• Power derate 1 |

|

| Engine Warning Light | ON | ON | |

| DTC Fault Code | P 0108 | P 0111 | P 0112 | |

|---|---|---|---|---|

| Name | MAP | IAT | IAT | |

| DTC Name | MAP high pressure | IAT Higher Than Expected Stage 1 | IAT Low Voltage | |

| J1939 | SPN | 106 | 105 | 105 |

| FMI | 16 | 15 | 4 | |

| MIL | ON | OFF | OFF | |

| Detected Item | • Sensor/wiring harness short to power

• Sensor malfunction |

• Intake air temperature abnormality

(High side stage 1) |

• Sensor / wiring harness short to ground

• Sensor malfunction |

|

| DTC Set Preconditions | • Engine Cranking or Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • MAP pressure > 110.3 kPa [abs]

(1.125 kgf/cm2, 16.00 psia) • and TPS < 3.0 % • and RPM > 1000 min-1 (rpm) |

• rum-time wait for all IAT HiExp faults 0.0 sec

• IAT > 71 degC (160 degF) • and RPM > 1000 min-1 (rpm) |

• IAT voltage < 0.100 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 2 sec | • 60 sec | • 1 sec | |

| System Action | • AL Disable KC

• Power derate 1 |

• AL Disable

• Power derate 1 |

• AL Disable

• Power derate 1 |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0113 | P 0116 | P 0117 | |

|---|---|---|---|---|

| Name | IAT | ECT/CHT | ECT/CHT | |

| DTC Name | IAT High Voltage | ECT Higher Than Expected Stage 1 | ECT/CHT Low Voltage | |

| J1939 | SPN | 105 | 110 | 110 |

| FMI | 3 | 15 | 4 | |

| MIL | OFF | OFF | OFF | |

| Detected Item | • Sensor/wiring harness open/short to power

• Sensor malfunction |

• Engine coolant temperature abnormality (High side stage 1) | • Sensor/wiring harness short to ground

• Sensor malfunction |

|

| DTC Set Preconditions | • Engine Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • IAT voltage > 4.90 V | • run time wait for ECT HiExp faults 30.0 sec

• ECT > 110 degC (230 degF) • and RPM > 600 min-1 (rpm) |

• ECT voltage < 0.100 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 20 sec | • 1 sec | |

| System Action | • AL Disable

• Power derate 1 |

• AL Disable

• Power derate 1 |

• AL Disable

• Power derate 1 |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0118 | P 0121 | P 0122 | |

|---|---|---|---|---|

| Name | ECT/CHT | TPS | TPS | |

| DTC Name | ECT/CHT High Voltage | TPS1 % Lower Than TPS2 % | TPS1 Signal Voltage Low | |

| J1939 | SPN | 110 | 51 | 51 |

| FMI | 3 | 1 | 4 | |

| MIL | OFF | ON | ON | |

| Detected Item | • Sensor/wiring harness open/short to power

• Sensor malfunction |

• TPS malfunction | • TPS circuit in the harness short to ground

• TPS malfunction |

|

| DTC Set Preconditions | • Engine Running | • Key-On, Engine Cranking, or Running | • Key-On, Engine Cranking, or Running | |

| DTC Set Conditions | • ECT voltage > 4.90 V | • (TPS1 %TPS2 %) < 20.0 % | • TPS1 voltage < 0.200 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 1 sec | • 0.5 sec | |

| System Action | • AL Disable

• Power derate 1 |

• Shutdown | • Shutdown | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0123 | P 0127 | P 0129 | |

|---|---|---|---|---|

| Name | TPS | IAT | IAT | |

| DTC Name | TPS1 Signal Voltage High | IAT Higher Than Expected Stage 2 | BP Low Pressure | |

| J1939 | SPN | 51 | 105 | 108 |

| FMI | 3 | 0 | 1 | |

| MIL | ON | OFF | ON | |

| Detected Item | • TPS circuit in the harness short to power

• TPS malfunction |

• Intake air temperature abnormality (High side stage 2) | • Sensor out of calibration

• Loss for 5V reference feed • (5V_ext1) to MAP • Signal wire open or shorted to ground |

|

| DTC Set Preconditions | • Key-On, Engine Cranking, or Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • TPS1 voltage > 4.80 V | • rum-time wait for all IAT HiExp faults 0.0 sec

• IAT > 93 degC (200 degF) • and RPM > 1000 min-1 (rpm) |

• BP < 57.2 kPa [abs]

(0.584 kgf/cm2, 8.30 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 0.5 sec | • 120 sec | • 1 sec | |

| System Action | • Shutdown | • AL Disable

• Force idle |

• AL Disable KC | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0134 | P 0154 | P 0171 | |

|---|---|---|---|---|

| Name | EGO Sensors | EGO Sensors | Adaptive Learn | |

| DTC Name | EGO1 Open/Lazy (HO2S1) | EGO2 Open/Lazy (HO2S2) | Adaptive Learn Bank 1 High (Gasoline) | |

| J1939 | SPN | 3217 | 3227 | 4237 |

| FMI | 5 | 5 | 0 | |

| MIL | ON | ON | ON | |

| Detected Item | • Open feed circuit to O2 heater

• Open heater ground circuit • Open or shorted to ground O2 signal wire • open sensor ground (5Vrtn1) • inoperative sensor |

• Open feed circuit to O2 heater

• Open heater ground circuit • Open or shorted to ground O2 signal wire • open sensor ground (5Vrtn1) • inoperative sensor |

• exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure to the fuel injection system • a inoperative sensor • an injector that is stuck closed or dirty • weak spark or lack of spark to a cylinder • a MAP sensor that indicates pressure that is lower than ture pressure |

|

| DTC Set Preconditions | • Engine Running | • Engine Running | • Engine Running, Adaptive Mode | |

| DTC Set Conditions | • EGO cold persistently > 120.0 sec | • EGO cold persistently > 120.0 sec | • AL_BM > 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 5 sec | • 5 sec | • 3 updates | |

| System Action | • CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0172 | P 0182 | P 0183 | |

|---|---|---|---|---|

| Name | Adaptive Learn | FT | FT | |

| DTC Name | Adaptive Learn Bank1 Low (Gasoline) | FT gasoline low | FT gasoline high | |

| J1939 | SPN | 4237 | 174 | 174 |

| FMI | 1 | 4 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • an inoperative O2 sensor

• high fuel supply pressure or temperature • internal mechanical engine damage • an injector that is stuck open or leaking |

• Operating in a frigid atmosphere

• Sensor out of calibration |

• Operating in a hot environment

• Sensor out of calibration |

|

| DTC Set Preconditions | • Engine Running, Adaptive Mode | • Engine Running | • Engine Running | |

| DTC Set Conditions | • AL_BM < 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• FT fault mode Temp only

• fuel temp < 37.0 degC (35.0 degF) |

• FT fault mode Temp only

• fuel temp > 60.0 degC (140.0 degF) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 3 updates | • 1 sec | • 1 sec | |

| System Action | • CL Disable

• AL Disable KC |

• | • Power derate 2 | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0187 | P 0217 | P 0219 | |

|---|---|---|---|---|

| Name | FT | ECT/CHT | Engine Speed | |

| DTC Name | FT Gaseous Fuel Extremery Low | ECT Higher Than Expected 2 | RPM Higher Than Max Allowed Governed Speed | |

| J1939 | SPN | 3468 | 110 | 515 |

| FMI | 1 | 0 | 15 | |

| MIL | ON | OFF | OFF | |

| Detected Item | • Not vaporized completely | • Engine coolant temperature abnormality (High side stage 2) | • Engine over speed condition, stuck throttle, large vacuum leak into intake manifold after throttle blade | |

| DTC Set Preconditions | • Engine Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • Fuel temp < 40 °C (40 °F) | • run time wait for ECT HiExp faults 30.0 sec

• ECT > 116 degC (240 degF) • and RPM > 600 min-1 (rpm) |

• RPM > 3800 min-1 (rpm) | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 30 sec | • 1 sec | |

| System Action | • | • Power derate 2 | • reduce throttle to limit speed | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0221 | P 0222 | P 0223 | |

|---|---|---|---|---|

| Name | TPS | TPS | TPS | |

| DTC Name | TPS1 % Higher Than TPS2 % | TPS2 Signal Voltage Low | TPS2 Signal Voltage High | |

| J1939 | SPN | 51 | 3673 | 3673 |

| FMI | 0 | 4 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • TPS malfunction | • TPS circuit in the harness short to ground

• TPS malfunction |

• TPS circuit in the harness short to power

• TPS malfunction |

|

| DTC Set Preconditions | • Key-On, Engine Cranking, or Running | • Key-On, Engine Cranking, or Running | • Key-On, Engine Cranking, or Running | |

| DTC Set Conditions | • (TPS1 %TPS2 %) > 20.0 % | • TPS2 voltage < 0.200 V | • TPS2 voltage > 4.80 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 0.5 sec | • 0.5 sec | |

| System Action | • Shutdown | • Shutdown | • Shutdown | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0261 | P 0262 | P 0264 | |

|---|---|---|---|---|

| Name | Injectors | Injectors | Injectors | |

| DTC Name | Injector Driver #1 Open / Short-To-Ground | Injector Driver #1 Short-To-Power | Injector Driver #2 Open / Short-To-Ground | |

| J1939 | SPN | 651 | 651 | 652 |

| FMI | 5 | 6 | 5 | |

| MIL | ON | ON | ON | |

| Detected Item | • Loss of 12.0 V feed to injector

• open injector coil • open or shorted to ground injector driver circuit in engine harness |

• Injector coil shorted internally

• Injector driver circuit shorted to voltage between injector and ECM |

• Loss of 12.0 V feed to injector

• open injector coil • open or shorted to ground injector driver circuit in engine harness |

|

| DTC Set Preconditions | • Key-On, Engine Running | • Key-On, Engine Running | • Key-On, Engine Running | |

| DTC Set Conditions | • Injector1 off-state low-side < 4.00 V • and battery voltage > 9.00 V | • Injector1 on-state low-side > 4.00 V

• and battery voltage < 16.0 V |

• Injector2 off-state low-side < 4.00 V • and battery voltage > 9.00 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 samples | • 10 samples | • 10 samples | |

| System Action | • CL Disable

• AL Disable KC • Low Rev Limit |

• CL Disable

• AL Disable KC • Low Rev Limit |

• CL Disable

• AL Disable KC • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0265 | P 0267 | P 0268 | |

|---|---|---|---|---|

| Name | Injectors | Injectors | Injectors | |

| DTC Name | Injector Driver #2 Short-To-Power | Injector Driver #3 Open/Short-To-Ground | Injector Driver #3 Short-To-Power | |

| J1939 | SPN | 652 | 653 | 653 |

| FMI | 6 | 5 | 6 | |

| MIL | ON | ON | ON | |

| Detected Item | • Injector coil shorted internally

• Injector driver circuit shorted to voltage between injector and ECM |

• Loss of 12.0 V feed to injector

• open injector coil • open or shorted to ground injector driver circuit in engine harness |

• Injector coil shorted internally

• Injector driver circuit shorted to voltage between injector and ECM |

|

| DTC Set Preconditions | • Key-On, Engine Running | • Key-On, Engine Running | • Key-On, Engine Running | |

| DTC Set Conditions | • Injector2 on-state low-side > 4.00 V

• and battery voltage < 16.0 V |

• Injector3 off-state low-side < 4.00 V • and battery voltage > 9.00 V | • Injector3 on-state low-side > 4.00 V

• and battery voltage < 16.0 V |

|

| Period for Judgment or Number of Occurrence for Judgment | • 10 samples | • 10 samples | • 10 samples | |

| System Action | • CL Disable

• AL Disable KC • Low Rev Limit |

• CL Disable

• AL Disable KC • Low Rev Limit |

• CL Disable

• AL Disable KC • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0270 | P 0271 | P 0326 | |

|---|---|---|---|---|

| Name | Injectors | Injectors | Knock | |

| DTC Name | Injector Driver #4 Open/Short-To-Ground | Injector Driver #4 Short-To-Power | Knock 1 Excessive or Erratic Signal | |

| J1939 | SPN | 654 | 654 | 731 |

| FMI | 5 | 6 | 2 | |

| MIL | ON | ON | ON | |

| Detected Item | • Loss of 12.0 V feed to injector

• open injector coil • open or shorted to ground injector driver circuit in engine harness |

• Injector coil shorted internally

• Injector driver circuit shorted to voltage between injector and ECM |

• Knock signal abnormality (High side)

• Sensor malfunction |

|

| DTC Set Preconditions | • Key-On, Engine Running | • Key-On, Engine Running | • Key On, Engine On | |

| DTC Set Conditions | • Injector4 off-state low-side < 4.00 V • and battery voltage > 9.00 V | • Injector4 on-state low-side > 4.00 V

• and battery voltage < 16.0 V |

• KNK1 sensor input > 0.500 V

• MAP < 55.2 kPa [abs] (0.562 kgf/cm2, 8.00 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 10 samples | • 10 samples | • 3 sec | |

| System Action | • CL Disable

• AL Disable KC • Low Rev Limit |

• CL Disable

• AL Disable KC • Low Rev Limit |

• Power derate 1

• Retard Fault KNK |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0327 | P 0336 | P 0337 | |

|---|---|---|---|---|

| Name | Knock | Cam/Crank Sensors | Cam/Crank Sensors | |

| DTC Name | Knock 1 Sensor Open or Not Present | Crank Input Signal Noise | Loss of Crankshaft Input Signal | |

| J1939 | SPN | 731 | 636 | 636 |

| FMI | 4 | 2 | 4 | |

| MIL | ON | ON | ON | |

| Detected Item | • Sensor/wiring harness open/short to power

• Sensor malfunction |

• Crank+ or Crank circuits in wrong connector terminal slot | • Loss of sensor feed

• open sensor ground • open or shorted to ground signal wire |

|

| DTC Set Preconditions | • Key On, Engine On | • Key On, Engine On | • Key On, Engine On | |

| DTC Set Conditions | • KNK1 sensor input < 0.005 V • and RPM > 2000 min-1 (rpm)

• and MAP > 82.7 kPa [abs] (0.844 kgf/cm2, 12.00 psia) |

• Number of invalid cam re-syncs 3 re-syncs

• within a time window of <= 800 ms |

• Cam pulsed without crank activity > 3 cam pulses | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 sec | • 1 sec | • 1 sec | |

| System Action | • Power derate 1

• Retard Fault KNK |

• AL Disable KC | • | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 0341 | P 0342 | P 0359 | |

|---|---|---|---|---|

| Name | Cam/Crank Sensors | Cam/Crank Sensors | Lockoff/Fuel Diagnostics | |

| DTC Name | Camshaft Input Signal Noise | Loss of Camshaft Input Signal | Fuel run-out longer than expected | |

| J1939 | SPN | 723 | 723 | 632 |

| FMI | 2 | 4 | 31 | |

| MIL | ON | ON | ON | |

| Detected Item | • Cam+ or Cam circuits in wrong connector terminal slot | • Loss of feed voltage to Cam sensor

• loss of signal or ground circuits • faulty sensor |

||

| DTC Set Preconditions | • Key On, Engine On | • Key On, Engine On | • Key Off, Engine On | |

| DTC Set Conditions | • Number of invalid cam re-syncs 3 re-syncs

• within a time window of <= 700 ms |

• No cam pulse in 2.0 cycles

• and RPM > 150 min-1 (rpm) |

• Fuel run-out engine run time >

20000 ms |

|

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 1 sec | • N/A | |

| System Action | • AL Disable KC | • AL Disable KC | • Shutdown | |

| Engine Warning Light | ON | ON | OFF | |

| DTC Fault Code | P 0420 | P 0524 | P 0562 | |

|---|---|---|---|---|

| Name | Catalyst | Oil Pressure | Battery Voltage | |

| DTC Name | Catalyst Monitor | Oil Pressure Low | Battery Voltage (VBAT) Low | |

| J1939 | SPN | 3050 | 100 | 168 |

| FMI | 11 | 1 | 17 | |

| MIL | OFF | ON | ON | |

| Detected Item | • Low Oil Pressure | • Wiring harness open / short / damage

• Battery abnormality |

||

| DTC Set Preconditions | • Engine Running | • Key On, Engine On | • Key On, Engine On | |

| DTC Set Conditions | • EGO3/4 RMS > 0.008 phi

• and EGO3/4 RMS > EGO1/2 RMS 50 % • and EGO3/4 RMS > CL waveform RMS 50 % • and mass flow at ports >= 10.0 g/sec and <= CBT CBT_ss +/50.0 degF |

• run time wait for oil pressure low faults 4.0 sec

• RPM lower limit for oil pressure low faults 300 min-1 (rpm) • Oil pressure pulled-up input less than a threshold voltage of 2.50 V |

• Voltage < 9.00 V • and RPM > 1000 min-1 (rpm) | |

| Period for Judgment or Number of Occurrence for Judgment | • 100 updates | • 1 sec | • 5 sec | |

| System Action | • Shutdown

• CL Disable • AL Disable • Hard Warning |

• Shutdown | • AL Disable KC

• Power derate 2 |

|

| Engine Warning Light | ON | ON | ON | |

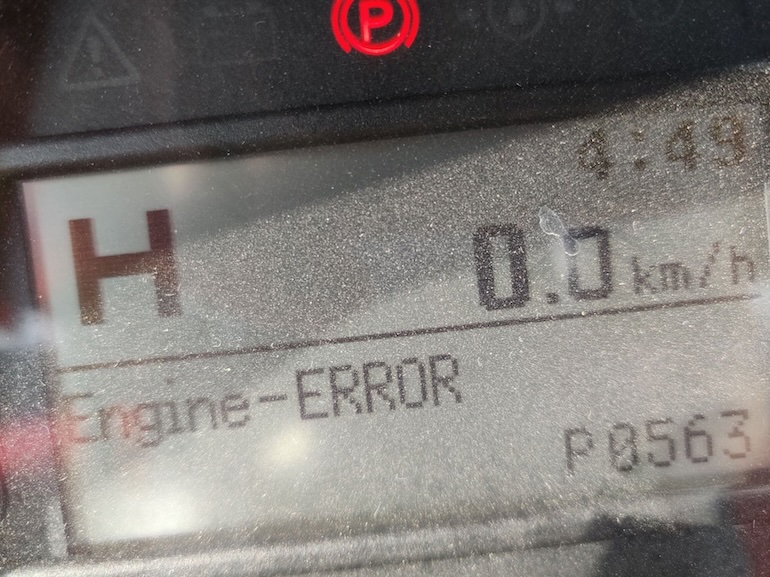

| DTC Fault Code | P 0563 | P 0601 | P 0604 | |

|---|---|---|---|---|

| Name | Battery Voltage | Internal Processor Diagnostics | Internal Processor Diagnostics | |

| DTC Name | Battery Voltage (VBAT) High | Microprocessor Failure-FLASH | Microprocessor Failure-RAM | |

| J1939 | SPN | 168 | 628 | 630 |

| FMI | 15 | 13 | 12 | |

| MIL | ON | ON | ON | |

| Detected Item | • System voltage abnormality (High side) | • Faulty ECU | • Faulty ECU | |

| DTC Set Preconditions | • Key-On, Engine Cranking, or Running | • Key on | • Key on | |

| DTC Set Conditions | • Voltage > 16.00 V | • Internal microprocessor error | • Internal ECM microprocessor memory access failure | |

| Period for Judgment or Number of Occurrence for Judgment | • 3 sec | • N/A | • N/A | |

| System Action | • AL Disable KC

• Low Rev Limit |

• Never Forget

• AL Disable KC • Power derate 2 |

• Never Forget

• AL Disable KC • Power derate 2 |

|

| Engine Warning Light | ON | OFF | OFF | |

| DTC Fault Code | P 0606 | P 0627 | P 0628 | ||

|---|---|---|---|---|---|

| Name | Internal Processor Diagnostics | Fuel Pump Relay Control/Coil | Fuel Pump Relay Control/Coil | Fuel Pump Motor Feedback | |

| DTC Name | Microprocessor Failure-COP | Fuel Pump Relay Coil Open | Fuel Pump Relay Ground Short | ||

| J1939 | SPN | 629 | 1348 | 1348 | 1347 |

| FMI | 31 | 5 | 4 | 5 | |

| MIL | ON | ON | ON | ON | |

| Detected Item | • Faulty ECU | • Open coil in relay

• Open in relay driver circuit in engine harness |

• Relay pull in coil shorted internally

• relay driver circuit shorted to ground in wire harness |

||

| DTC Set Preconditions | • Key on | • Key On, Engine Off | • Engine Running | • Engine Running | |

| DTC Set Conditions | • Internal microprocessor error | • Fuel Pump relay coil output open circuit | • Fuel Pump relay coil output shorted to ground | • Fuel pump motor high-side on-state < 4.0 volts • battery voltage > 8.0 volts | |

| Period for Judgment or Number of Occurrence for Judgment | • N/A | • 10 samples | • 10 samples | • 2 sec | |

| System Action | • Never Forget

• AL Disable KC • Power derate 2 |

• | • | • | |

| Engine Warning Light | OFF | ON | ON | ON | |

| DTC Fault Code | P 0629 | P 0642 | P 0643 | ||

|---|---|---|---|---|---|

| Name | Fuel Pump Relay Control/Coil | Fuel Pump Motor Feedback | 5 V External | 5 V External | |

| DTC Name | Fuel Pump Relay Coil Short-To-Power | Sensor Supply Voltage 1 Low (5Vext1) | Sensor Supply Voltage 1 High (5Vext1) | ||

| J1939 | SPN | 1348 | 1347 | 1079 | 1079 |

| FMI | 3 | 6 | 4 | 3 | |

| MIL | ON | ON | ON | ON | |

| Detected Item | • Shorted relay pull in coil

• relay driver circuit shorted to voltage in wire harness |

• Wiring harness short to ground

• ECM malfunction |

• Wiring harness short to 12.0 V power

• ECM malfunction |

||

| DTC Set Preconditions | • Engine Running | • Key-On, Engine OFF, or Running | • Key-On, Engine OFF, or Running | • Key-On, Engine OFF, or Running | |

| DTC Set Conditions | • Fuel Pump relay coil output short to power/ voltage | • Fuel pump motor high-side

off-state < 4.0 volts • battery voltage < 16.0 volts |

• 5VE1 < 4.60 V | • 5VE1 > 5.40 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 samples | • 2 sec | • 1 sec | • 1 sec | |

| System Action | • | • | • AL Disable

• Power derate 1 |

• AL Disable

• Power derate 1 |

|

| Engine Warning Light | ON | ON | ON | ON | |

| DTC Fault Code | P 0652 | P 0653 | P 0686 | |

|---|---|---|---|---|

| Name | 5 V External | 5 V External | Power Relay Control/Coil | |

| DTC Name | Sensor Supply Voltage 2 Low (5Vext2) | Sensor Supply Voltage 2 High (5Vext2) | Power Relay Ground Short | |

| J1939 | SPN | 1080 | 1080 | 1485 |

| FMI | 4 | 3 | 4 | |

| MIL | ON | ON | ON | |

| Detected Item | • Wiring harness short to ground

• ECM malfunction |

• Wiring harness short to 12.0 V power

• ECM malfunction |

• Short to ground in relay pull in coil

• short to ground in relay driver circuit in wire harness |

|

| DTC Set Preconditions | • Key-On, Engine OFF, or Running | • Key-On, Engine OFF, or Running | • Key On, Engine Off | |

| DTC Set Conditions | • 5VE2 < 4.60 V | • 5VE2 > 5.40 V | • Power relay coil output shorted to ground | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 1 sec | • 10 samples | |

| System Action | • AL Disable

• Power derate 1 |

• AL Disable

• Power derate 1 |

• | |

| Engine Warning Light | ON | ON | OFF | |

| DTC Fault Code | P 0687 | P 1111 | P 1112 | |

|---|---|---|---|---|

| Name | Power Relay Control/Coil | Engine Speed | Engine Speed | |

| DTC Name | Power Relay Coil Short-To-Power | RPM Above Fuel Rev Limit Level | RPM Above Spark Rev Limit Level | |

| J1939 | SPN | 1485 | 515 | 515 |

| FMI | 3 | 16 | 0 | |

| MIL | ON | ON | ON | |

| Detected Item | • Shorted relay pull in coil

• relay driver circuit shorted to voltage in wire harness |

• Engine overspeed condition, faulty

• Crank sensor or input |

• Engine overspeed condition, faulty

• Crank sensor or input |

|

| DTC Set Preconditions | • Key On, Engine Off | • Engine Running | • Engine Running | |

| DTC Set Conditions | • Power relay coil output short to power/voltage | • RPM > 4200 min-1 (rpm) | • RPM > 4300 min-1 (rpm) | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 samples | • 1 sec | • 1 sec | |

| System Action | • | • disable fuel injectors or gaseous fuel control actuator | • disable ignition coils | |

| Engine Warning Light | OFF | ON | ON | |

| DTC Fault Code | P 1121 | P 1151 | P 1152 | |

|---|---|---|---|---|

| Name | FPP | Closed Loop | Closed Loop | |

| DTC Name | FPP1/2 Simultaneous Voltages Out-of-Range | Closed Loop High (LPG) | Closed Loop Low (LPG) | |

| J1939 | SPN | 91 | 4236 | 4236 |

| FMI | 31 | 0 | 1 | |

| MIL | ON | ON | ON | |

| Detected Item | • Wiring harness open / short / damage

• FPP malfunction |

• exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure to the gaseous fuel control system • a fuel supply or manifold leak • a non-responsive HEGO sensor |

• high fuel supply pressure to the gaseous fuel control or faulty pressure regulator

• a non-responsive HEGO sensor |

|

| DTC Set Preconditions | • Key on, Engine Off | • Engine Running, Closed Loop Mode | • Engine Running, Closed Loop Mode | |

| DTC Set Conditions | • User same parameter as individual FPP 1/2 voltage fault detection above | • CL_BM > 35 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• CL_BM < 35 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 0.5 sec | • Power Derate2

• 5 updates |

• 5 updates | |

| System Action | • Power Derate 2

• Low Rev Limit • Force Idle |

• CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

|

| Engine Warning Light | OFF | ON | ON | |

| DTC Fault Code | P 1153 | P 1154 | P 1155 | |

|---|---|---|---|---|

| Name | Closed Loop | Closed Loop | Closed Loop | |

| DTC Name | Closed Loop High (NG) | Closed Loop Low (NG) | Closed Loop Bank 1 High (Gasoline) | |

| J1939 | SPN | 4236 | 4236 | 4236 |

| FMI | 0 | 1 | 0 | |

| MIL | ON | ON | ON | |

| Detected Item | • exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure to the gaseous fuel control system • a fuel supply or manifold leak • a non-responsive HEGO sensor |

• high fuel supply pressure to the gaseous fuel control or faulty pressure regulator

• a non-responsive HEGO sensor |

• exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure • an injector that is stuck closed |

|

| DTC Set Preconditions | • Engine Running, Closed Loop Mode | • Engine Running, Closed Loop Mode | • Engine Running, Closed Loop Mode | |

| DTC Set Conditions | • CL_BM > 35 % • and RPM <= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• CL_BM < 35 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• CL_BM > 35 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 5 updates | • 5 updates | • 5 updates | |

| System Action | • CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1156 | P 1161 | P 1162 | |

|---|---|---|---|---|

| Name | Closed Loop | Adaptive Learn | Adaptive Learn | |

| DTC Name | Closed Loop Bank 1 Low (Gasoline) | Adaptive Learn High (LPG) | Adaptive Learn Low (LPG) | |

| J1939 | SPN | 4236 | 4237 | 4237 |

| FMI | 1 | 0 | 1 | |

| MIL | ON | ON | ON | |

| Detected Item | • high fuel supply pressure to the fuel injection system

• a non-responsive HEGO sensor • an injector that is stuck open |

• exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure to the gaseous fuel control system • a fuel supply or manifold leak • a non-responsive HEGO sensor |

• high fuel supply pressure to the gaseous fuel control or faulty pressure regulator

• a non-responsive HEGO sensor |

|

| DTC Set Preconditions | • Engine Running, Closed Loop Mode | • Engine Running, Adaptive Mode | • Engine Running, Adaptive Mode | |

| DTC Set Conditions | • CL_BM < 35 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• AL_BM > 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• AL_BM < 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 5 updates | • 3 updates | • 3 updates | |

| System Action | • CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1163 | P 1164 | P 1165 | |

|---|---|---|---|---|

| Name | Adaptive Learn | Adaptive Learn | Catalyst | |

| DTC Name | Adaptive Learn High (NG) | Adaptive Learn Low (NG) | Catalyst inactive on LPG | |

| J1939 | SPN | 4237 | 4237 | 3050 |

| FMI | 0 | 1 | 11 | |

| MIL | ON | ON | OFF | |

| Detected Item | • exhaust leaks upstream or near the HEGO sensor

• reduced fuel supply pressure to the gaseous fuel control system • a fuel supply or manifold leak • a non-responsive HEGO sensor |

• high fuel supply pressure to the gaseous fuel control or faulty pressure regulator

• a non-responsive HEGO sensor |

• N/A | |

| DTC Set Preconditions | • Engine Running, Adaptive Mode | • Engine Running, Adaptive Mode | • Engine Running | |

| DTC Set Conditions | • AL_BM > 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• AL_BM < 30 % • and RPM >= 0 min-1 (rpm) • and RPM <= 9999 min-1 (rpm) • and MAP >= 0.0 kPa [abs] (0.0 kgf/cm2, 0.0 psia) • and MAP <= 682 kPa [abs] (6.96 kgf/cm2, 99.0 psia) |

• EGO3/4 RMS > 0.008 phi and EGO3/4 RMS > EGO1/2 RMS 50 %

• and EGO3/4 RMS > CL waveform RMS 50 % • and mass flow at ports >= 10.0 g/sec and <= CBT CBT_ss +/50.0 degF |

|

| Period for Judgment or Number of Occurrence for Judgment | • 3 updates | • 3 updates | • 100 updates | |

| System Action | • CL Disable

• AL Disable KC |

• CL Disable

• AL Disable KC |

• Shutdown

• CL Disable • AL Disable • Hard Warning |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1166 | P 1171 | P 1172 | |

|---|---|---|---|---|

| Name | Catalyst | EPR Diagnostics | EPR Diagnostics | |

| DTC Name | Catalyst inactive on NG | EPR/CFV Regulation Pressure Higher than Expected | EPR/CFV Regulation Pressure Lower than Expected | |

| J1939 | SPN | 3050 | 520260 | 520260 |

| FMI | 11 | 0 | 1 | |

| MIL | OFF | ON | ON | |

| Detected Item | • Catalyst inactive on NG | • Inlet pressure to DEPR is too high. | • Inlet pressure to DEPR is too low.

• Malfunctioning lock off valve, plugged fuel filter, closed manual valve or fuel tank out of fuel |

|

| DTC Set Preconditions | • Engine Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • EGO3/4 RMS > 0.008 phi and EGO3/4 RMS > EGO1/2 RMS 50 % and EGO3/4 RMS > CL waveform RMS 50 % and mass flow at ports >= 10.0 g/sec and <= CBTCBT_ss +/50.0 degF | • EPR actual-commanded pressure > 2.50 in H2O | • EPR actual-commanded pressure < -2.50 in H2O | |

| Period for Judgment or Number of Occurrence for Judgment | • 100 updates | • 5 sec | • 5 sec | |

| System Action | • CL Disable

• AL Disable KC |

• AL Disable | • AL Disable | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1173 | P 1174 | P 1175 | |

|---|---|---|---|---|

| Name | EPR Diagnostics | EPR Diagnostics | EPR Diagnostics | |

| DTC Name | EPR/CFV comm lost | EPR/CFV Voltage Supply High | EPR/CFV Voltage Supply Low | |

| J1939 | SPN | 520620 | 520260 | 520260 |

| FMI | 31 | 3 | 4 | |

| MIL | OFF | ON | ON | |

| Detected Item | • Faulty CAN cinnection

• CAN terminal incorrect |

• Supply voltage to the EPR/CFV is too high | • Supply voltage to the EPR/CFV is too low | |

| DTC Set Preconditions | • Engine Running | • Engine Running | • Engine Running | |

| DTC Set Conditions | • No EPR packets recieved within 500 ms | • Voltage supply to EPR/CFV is > 33.0 VDC | • Voltage supply to EPR/CFV is < 18.0 VDC | |

| Period for Judgment or Number of Occurrence for Judgment | • 0.5 sec | • 5 sec | • 5 sec | |

| System Action | • CL Disable

• AL Disable KC |

• AL Disable

• AL Disable KC • Power Derate 2 • Low Rev Limit |

• AL Disable

• AL Disable KC • Power Derate 2 • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1176 | P 1177 | P 1274 | |

|---|---|---|---|---|

| Name | EPR Diagnostics | EPR Diagnostics | Pump Seizing Error | |

| DTC Name | EPR/CFV Internal Actuator Fault Detection | EPR/CFV Internal Circuitry Fault Detection | Pump seizing 1 | |

| J1939 | SPN | 520260 | 520260 | 523539 |

| FMI | 12 | 12 | 2 | |

| MIL | ON | ON | ON | |

| Detected Item | • Short or open circuit in actuator coil

• Associated wiring • Overheating of actuator drive electronics |

• DEPR internal microprocessor or memory failure, fuel temperature sensor failure. | • High pressure 1 error | |

| DTC Set Preconditions | • Engine Running | • Engine Running | • Sensor supply voltage VCC# is normal • Rail pressure sensor is normal |

|

| DTC Set Conditions | • the DEPR electronics detect a fault condition associated with its internal actuator. | • the DEPR electronics detect a fault condition associated with its internal circuitry. | • (Approximate parameter) Rail pressure of 300 MPa (3059 kg/cm2, 43500 psi) or more continues one sec under the condition of 500 rpm or more • [Threshold changes depending on the engine speed. 2600 rpm should be used as a reference] |

|

| Period for Judgment or Number of Occurrence for Judgment | • 0.25 sec | • 0.25 sec | • one time or more | |

| System Action | • AL Disable | • AL Disable | • Engine stop | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1275 | P 1612 | P 1613 | |

|---|---|---|---|---|

| Name | Pump Seizing Error | Internal Processor Diagnostics | Internal Processor Diagnostics | |

| DTC Name | Pump seizing 2 | Microprocessor Failure-RTI 1 | Microprocessor Failure-RTI 2 | |

| J1939 | SPN | 523540 | 629 | 629 |

| FMI | 2 | 31 | 31 | |

| MIL | ON | ON | ON | |

| Detected Item | • High pressure 2 error | • Faulty ECU | • Faulty ECU | |

| DTC Set Preconditions | • Sensor supply voltage VCC# is normal • Rail pressure sensor is normal |

• Key on | • Key on | |

| DTC Set Conditions | • (Approximate parameter) Rail pressure of more than 267 MPa (2723 kg/cm2, 38700 psi), and less than 300 MPa (3059 kg/cm2, 43500 psi) continues total time for 35 seconds • [Threshold changes depending on the engine speed. 2600 rpm should be used as a reference] • Or, rail pressure of more than 107 MPa (1091 kg/cm2, 15500 psi) and less than 195 MPa (1988 kg/cm2, 28300 psi) continues total time for 35 seconds • [Threshold changes depending on the engine speed. 200 rpm should be used as a reference] |

• Internal microprocessor error | • Internal microprocessor error | |

| Period for Judgment or Number of Occurrence for Judgment | • one time or more | • N/A | • N/A | |

| System Action | • Engine stop | • Shutdown

• CL Disable • AL Disable • Hard Warning |

• Never Forget

• AL Disable KC • Power derate 2 |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 1614 | P 1615 | P 1616 | |

|---|---|---|---|---|

| Name | Internal Processor Diagnostics | Internal Processor Diagnostics | Internal Processor Diagnostics | |

| DTC Name | Microprocessor Failure-RTI 3 | Microprocessor Failure-A/D | Microprocessor Failure-Interrupt | |

| J1939 | SPN | 629 | 629 | 629 |

| FMI | 31 | 31 | 31 | |

| MIL | ON | ON | ON | |

| Detected Item | • Faulty ECU | • Faulty ECU | • Faulty ECU | |

| DTC Set Preconditions | • Key on | • Key on | • Key on | |

| DTC Set Conditions | • Internal microprocessor error | • Internal microprocessor error | • Internal microprocessor error | |

| Period for Judgment or Number of Occurrence for Judgment | • N/A | • N/A | • N/A | |

| System Action | • Never Forget

• AL Disable KC • Power derate 2 |

• Never Forget

• AL Disable KC • Power derate 2 |

• Never Forget

• AL Disable KC • Power derate 2 |

|

| Engine Warning Light | ON | OFF | OFF | |

| DTC Fault Code | P 1673 | P 1990 | P 1A06 | |

|---|---|---|---|---|

| Name | General System Diagnostics | Kubota EEPROM check sum error | High pressure delivery system | |

| DTC Name | Calibration Configuration Error | EEPROM check sum error | High pressure delivery system too high | |

| J1939 | SPN | 1634 | 523700 | 523608 |

| FMI | 13 | 13 | 2 | |

| MIL | ON | ON | ON | |

| Detected Item | • ECM malfunction | • EEPROM check sum error | • High pressure delivery system too high |

|

| DTC Set Preconditions | • Key ON | • Battery voltage is normal | • Battery voltage is normal • Starter switch signal (ECU: V12 terminal) is not activated • During pump operating normally (Pump calibration is completed) • NE sensing is normal • The difference between the previous and current target pressure is 10 MPa or less • No electric noise in pressure sensing |

|

| DTC Set Conditions | • Specific calibration variable checks do not return expected results | • EEPROM check sum error | • Excessively operating of PRV error (Actual rail pressure > target rail pressure) occur in specified times | |

| Period for Judgment or Number of Occurrence for Judgment | • N/A | • transient | • transient | |

| System Action | • Never Forget

• AL Disable KC • Power derate 2 |

• N/A | • Output limitation: Approximately 50% of normal condition • Speed limitation (Accelerator limitation: 50%) • EGR stop |

|

| Engine Warning Light | OFF | ON | ON | |

| DTC Fault Code | P 2111 | P 2112 | P 2121 | |

|---|---|---|---|---|

| Name | TPS | TPS | FPP | |

| DTC Name | Unable to Reach Lower TPS | Unable to Reach Higher TPS | FPP1 Lower Than FPP2 | |

| J1939 | SPN | 51 | 51 | 91 |

| FMI | 7 | 7 | 18 | |

| MIL | ON | ON | ON | |

| Detected Item | • TPS malfunction | • TPS malfunction | • Wiring harness open / short / damage

• FPP malfunction |

|

| DTC Set Preconditions | • Cranking or Running | • Cranking or Running | • Key On, Engine Off | |

| DTC Set Conditions | • target TPS-actual TPS < 20.0 % • persistently longer than 200 ms while battery voltage > 9.00 V and battery voltage < 16.0 V | • target TPS-actual TPS > 20.0 %

• persistently longer than 200 ms while battery voltage > 9.00 V and battery voltage < 16.0 V |

• (FPP 1 % – FPP 2 %) < 20.0 % | |

| Period for Judgment or Number of Occurrence for Judgment | • 1 sec | • 1 sec | • 1.5 sec | |

| System Action | • Shutdown | • Shutdown | • Power derate 2

• Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2122 | P 2123 | P 2126 | |

|---|---|---|---|---|

| Name | FPP | FPP | FPP | |

| DTC Name | FPP1 Voltage High | FPP1 Voltage Low | FPP1 Higher Than FPP2 | |

| J1939 | SPN | 91 | 91 | 91 |

| FMI | 3 | 4 | 16 | |

| MIL | ON 2Hz | ON 2Hz | ON | |

| Detected Item | • Wiring harness open / short / damage

• FPP malfunction |

• Wiring harness open / short / damage

• FPP malfunction |

• Wiring harness open / short / damage

• FPP malfunction |

|

| DTC Set Preconditions | • Key On | • Key On, Engine Off | • Key On, Engine Off | |

| DTC Set Conditions | • FPP1 voltage > 4.80 V | • FPP1 voltage < 0.200 V | • (FPP 1 % – FPP 2 %) > 20.0 % | |

| Period for Judgment or Number of Occurrence for Judgment | • 0.5 sec | • 0.5 sec | • 1.5 sec | |

| System Action | • Power derate 1

• Low Rev Limit |

• Power derate 1

• Low Rev Limit |

• Power derate 2

• Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2127 | P 2128 | P 2135 | |

|---|---|---|---|---|

| Name | FPP | FPP | TPS | |

| DTC Name | FPP2 voltage low | FPP2 voltage high | TPS1/2 Simultaneous Voltages out of range | |

| J1939 | SPN | 29 | 29 | 51 |

| FMI | 4 | 3 | 31 | |

| MIL | ON 2Hz | ON 2Hz | ON | |

| Detected Item | • Wiring harness open / short / damage

• FPP malfunction |

• Wiring harness open / short / damage

• FPP malfunction |

• TPS malfunction | |

| DTC Set Preconditions | • Key On | • Key On | • Key On, Engine On | |

| DTC Set Conditions | • FPP1 voltage < 0.200 V | • FPP1 voltage > 4.80 V | • User same parameter as individual TPS1/2 voltage fault detection above | |

| Period for Judgment or Number of Occurrence for Judgment | • 0.5 sec | • 0.5 sec | • 0.5 sec | |

| System Action | • Power derate 1

• Low Rev Limit |

• Power derate 1

• Low Rev Limit |

• Shutdown | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2200 | P 220E | P 220F | |

|---|---|---|---|---|

| Name | Aftertreatment 1 Intake NOx | Aftertreatment 1 Intake Gas Sensor Heater Control | Aftertreatment 1 Outlet Gas Sensor Heater Control | |

| DTC Name | NOx Sensor Circuit Bank 1 Sensor 1 | NOx Sensor Heater Control Circuit Range/Performance Bank 1 Sensor 1 | NOx Sensor Heater Control Circuit Range/Performance Bank 1 Sensor 2 | |

| J1939 | SPN | 3216 | 3223 | 3233 |

| FMI | 12 | 12 | 6 | |

| MIL | ON | ON | ON | |

| Detected Item | • Abnormal voltage, instability of readings, open circuit, short circuit of NOx sensor | • Short or open circuit of NOx sensor heater | • Short or open circuit of NOx sensor heate | |

| DTC Set Preconditions | • Battery voltage is normal • IG switch signal (ECU: V13 & V33, ACU: 18 terminal) is continuously activated more than 2 sec • Starter switch signal (ECU: V12 terminal) is not activated except within 2 sec after starter stopped • CAN communication is normal between ACU and engine ECU • CAN communication is normal between ACU and Pre NOx sensor |

• Battery voltage is normal • IG switch signal (ECU: V13 & V33, ACU: 18 terminal) is continuously activated more than 2 sec • Starter switch signal (ECU: V12 terminal) is not activated except within 2 sec after starter stopped • CAN communication is normal between ACU and engine ECU • CAN communication is normal between ACU and Pre NOx sensor |

• Battery voltage is normal • IG switch signal (ECU: V13 & V33, ACU: 18 terminal) is continuously activated more than 2 sec • Starter switch signal (ECU: V12 terminal) is not activated except within 2 sec after starter stopped • CAN communication is normal between ACU and engine ECU • CAN communication is normal between ACU and Post NOx sensor |

|

| DTC Set Conditions | • NOx sensor CAN message is indicating NOx sensor error (Abnormal voltage, Instability of readings, Open circuit, Short circuit, Invalid NOx data, Invalid O2 data) • In spite of Pre NOx sensor operation is normal, NOx sensor CAN message is indicating NOx value are more than 3012 ppm or O2 value are more than 21% |

• NOx sensor CAN message is indicating • NOx sensor error (Open circuit or Short circuit of NOx sensor heater) |

• NOx sensor CAN message is indicating • NOx sensor error (Open circuit or Short circuit of NOx sensor heater) |

|

| Period for Judgment or Number of Occurrence for Judgment | • 3 sec or more | • 3 sec or more | • 3 sec or more | |

| System Action | • No action to protect hardware | • No action to protect hardware | • No action to protect hardware | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2228 | P 2229 | P 2293 | ||

|---|---|---|---|---|---|

| Name | Barometric Pressure | Barometric Pressure | Pressure relief valve error | PRV driving circuit error | |

| DTC Name | Barometric pressure sensor error (Low side) | Barometric pressure sensor error (High side) | Pressure relief valve error | PRV driving circuit error | |

| J1939 | SPN | 108 | 108 | 523606 | 523606 |

| FMI | 4 | 3 | 2 | 8 | |

| MIL | ON | ON | ON | ON | |

| Detected Item | • Sensor or ECU internal circuit short to ground | • Sensor or ECU internal circuit short to +B | • Pressure relief valve error | • PRV driving circuit error | |

| DTC Set Preconditions | • Battery voltage is normal | • Battery voltage is normal | • Battery voltage is normal • Starter switch signal (ECU: V12 terminal) is not activated • During pump operating normally (Pump calibration is completed) • NE sensing is normal • Injection Q is 0 mm3/s or less • Not occur tentative error of pressure • No electric noise in pressure sensing |

• Battery voltage is normal • During injection • CPU is normal (VDIC2 is normal) |

|

| DTC Set Conditions | • Barometric pressure sensor voltage: 1.6 V or less | • Barometric pressure sensor voltage: 4.4 V or more | • After pressure relief valve (PRV) driving, excessively more pressure than supposed is detected | • Open circuit of discharge MOS-IC in ECU | |

| Period for Judgment or Number of Occurrence for Judgment | • 2.8 sec or more | • 2.8 sec or more | • Transient | • 20 times or more | |

| System Action | • 65 kPa (0.663 kg/cm2, 9.43 psi) [default value] | • 65 kPa (0.663 kg/cm2, 9.43 psi) [default value | • Output limitation: Approximately 50% of normal condition • Speed limitation (Accelerator limitation: 50%) • EGR stop |

• Output limitation: Approximately 50% of normal condition • Speed limitation (Accelerator limitation: 50%) • EGR stop |

|

| Engine Warning Light | ON | ON | ON | ON | |

| DTC Fault Code | P 2294 | P 229E | P 2300 | |

|---|---|---|---|---|

| Name | Open circuit of harness | Aftertreatment 1 Outlet NOx | Spark Coil Primary | |

| DTC Name | Open circuit of harness or coil in PRV line | NOx Sensor Circuit Bank 1 Sensor 2 | Spark Coil #1 Primary Open/Short-to-Ground | |

| J1939 | SPN | 523613 | 3226 | 1268 |

| FMI | 5 | 12 | 5 | |

| MIL | ON | ON | ON | |

| Detected Item | • Open circuit of harness • Open circuit of PRV coil |

• Abnormal voltage, instability of readings, open circuit, short circuit of NOx senso | • a short to ground or open circuit in

the harness • an open internal to the primary coil |

|

| DTC Set Preconditions | • Battery voltage is normal • During PRV driving • CPU is normal (VDIC2 is normal) |

• Battery voltage is normal • IG switch signal (ECU: V13 & V33, ACU: 18 terminal) is continuously activated more than 2 sec • Starter switch signal (ECU: V12 terminal) is not activated except within 2 sec after starter stopped • CAN communication is normal between ACU and engine ECU • CAN communication is normal between ACU and Post NOx sensor |

• Key On, Engine On | |

| DTC Set Conditions | • Open circuit of harness or Open circuit of PRV coil | • NOx sensor CAN message is indicating NOx sensor error (Abnormal voltage, Instability of readings, Open circuit, Short circuit, Invalid NOx data, Invalid O2 data) • In spite of Post NOx sensor operation is normal, NOx sensor CAN message is indicating NOx value are more than 3012 ppm or O2 value are more than 21% |

• Adaptive dwell adjustment >= 2.0 ms or total dwell >= 14.0 ms and battery voltage > 11.0 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 8 times or more | • 3 sec or more | • 10 sparks | |

| System Action | • Output limitation: Approximately 50% of normal condition • Speed limitation (Accelerator limitation: 50%) • EGR stop |

• No action to protect hardware | • CL Disable

• AL Disable • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2301 | P 2303 | P 2304 | |

|---|---|---|---|---|

| Name | Spark Coil Primary | Spark Coil Primary | Spark Coil Primary | |

| DTC Name | Spark Coil #1 Primary Short-to-Power | Spark Coil #2 Primary Open/Short-to-Ground | Spark Coil #2 Primary Short-to-Power | |

| J1939 | SPN | 1268 | 1269 | 1269 |

| FMI | 6 | 5 | 6 | |

| MIL | ON | ON | ON | |

| Detected Item | • a short to power in the harness

• a short internal to the primary coil |

• a short to ground or open circuit in the harness

• an open internal to the primary coil |

• a short to power in the harness

• a short internal to the primary coil |

|

| DTC Set Preconditions | • Key On, Engine On | • Key On, Engine On | • Key On, Engine On | |

| DTC Set Conditions | • Adaptive dwell adjustment <= 2.0 ms or total dwell <= 4.0 ms and battery voltage < 16.0 V | • Adaptive dwell adjustment >= 2.0 ms or total dwell >= 14.0 ms and battery voltage > 11.0 V | • Adaptive dwell adjustment <= 2.0 ms or total dwell <= 4.0 ms and battery voltage < 16.0 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 sparks | • 10 sparks | • 10 sparks | |

| System Action | • CL Disable

• AL Disable • Low Rev Limit |

• CL Disable

• AL Disable • Low Rev Limit |

• CL Disable

• AL Disable • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2306 | P 2307 | P 2309 | |

|---|---|---|---|---|

| Name | Spark Coil Primary | Spark Coil Primary | Spark Coil Primary | |

| DTC Name | Spark Coil #3 Primary Open/Short-to-Ground | Spark Coil #3 Primary Short-to-Power | Spark Coil #4 Primary Open/Short-to-Ground | |

| J1939 | SPN | 1270 | 1270 | 1271 |

| FMI | 5 | 6 | 5 | |

| MIL | ON | ON | ON | |

| Detected Item | • a short to ground or open circuit in

the harness • an open internal to the primary coil |

• a short to power in the harness

• a short internal to the primary coil |

• a short to ground or open circuit in

the harness • an open internal to the primary coil |

|

| DTC Set Preconditions | • Key On, Engine On | • Key On, Engine On | • Key On, Engine On | |

| DTC Set Conditions | • Adaptive dwell adjustment >= 2.0 ms or total dwell >= 14.0 ms and battery voltage > 11.0 V | • Adaptive dwell adjustment <= 2.0 ms or total dwell <= 4.0 ms and battery voltage < 16.0 V | • Adaptive dwell adjustment >= 2.0 ms or total dwell >= 14.0 ms and battery voltage > 11.0 V | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 sparks | • 10 sparks | • 10 sparks | |

| System Action | • CL Disable

• AL Disable • Low Rev Limit |

• CL Disable

• AL Disable • Low Rev Limit |

• CL Disable

• AL Disable • Low Rev Limit |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2310 | P 2413 | P 2414 | |

|---|---|---|---|---|

| Name | Spark Coil Primary | EGR actuator valve stuck | EGR overheat | |

| DTC Name | Spark Coil #4 Primary Short-to-Power | EGR actuator valve stuck | EGR (DC motor) overheat | |

| J1939 | SPN | 1271 | 523575 | 523576 |

| FMI | 6 | 7 | 2 | |

| MIL | ON | ON | ON | |

| Detected Item | • a short to power in the harness

• a short internal to the primary coil |

• EGR actuator valve stuck | • EGR (DC motor) overheat | |

| DTC Set Preconditions | • Key On, Engine On | • Battery voltage is normal • NO DTC of U0077 “CAN1 Bus off” • EGR control line is normal |

• Battery voltage is normal • NO DTC of U0077 “CAN1 Bus off” • EGR control line is normal |

|

| DTC Set Conditions | • Adaptive dwell adjustment <= 2.0 ms or total dwell <= 4.0 ms and battery voltage < 16.0 V | • EGR actuator valve stuck error signal received via CAN | • EGR (DC motor) temp. error signal (thermistor: 125 deg. C or more) received via CAN | |

| Period for Judgment or Number of Occurrence for Judgment | • 10 sparks | • 2.8 sec or more | • 2.8 sec or more | |

| System Action | • CL Disable

• AL Disable • Low Rev Limit |

• Output limitation: Approximately 75% of normal condition • EGR stop |

• Output limitation: Approximately 75% of normal condition • EGR stop |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2415 | P 242C | P 242D | |

|---|---|---|---|---|

| Name | EGR temperature sensor failure | Aftertreatment 1 Diesel Particulate Filter Outlet Gas Temperature | Aftertreatment 1 Diesel Particulate Filter Outlet Gas Temperature | |

| DTC Name | EGR (DC motor) temp. sensor failure | Exhaust gas temperature sensor 2: Low | Exhaust gas temperature sensor 2: High | |

| J1939 | SPN | 523577 | 3246 | 3246 |

| FMI | 2 | 4 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • EGR (DC motor) temp. sensor failure | • Ground short circuit of sensor or harness | • Open circuit or +B short circuit of sensor or harness | |

| DTC Set Preconditions | • Battery voltage is normal • NO DTC of U0077 “CAN1 Bus off” • EGR control line is normal |

• Battery voltage is normal | • Battery voltage is normal • Coolant temp. is 65 deg. C (149 deg. F) or more: continues longer than 10 min after engine starting • T0 is between 100 deg. C (212 deg. F) and 800 deg. C (1472 deg. F): continues longer than 10 sec or T1 is between 100 deg. C (212 deg. F) and 800 deg. C (1472 deg. F): continues longer than 10 sec |

|

| DTC Set Conditions | • EGR (DC motor) temp. sensor error signal received via CAN | • DPF outlet temp. sensor (T2) voltage: 0.08 V or less | • DPF outlet temp. sensor (T2) voltage: 4.92 V or more | |

| Period for Judgment or Number of Occurrence for Judgment | • 2.8 sec or more | • 5 sec or more | • 120 sec or more | |

| System Action | • Output limitation: Approximately 75% of normal condition • EGR stop |

• 0 deg. C (32 deg. F) [default value] • Output limitation: Approximately 75% of normal condition |

• 0 deg. C (32 deg. F) [default value] • Output limitation: Approximately 75% of normal condition |

|

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2454 | P 2455 | P 260E | |

|---|---|---|---|---|

| Name | Aftertreatment 1 Diesel Particulate Filter Differential Pressure | Aftertreatment 1 Diesel Particulate Filter Differential Pressure | Active regeneration lamp error | |

| DTC Name | Differential pressure sensor 1: Low | Differential pressure sensor 1: High | Active regeneration lamp error | |

| J1939 | SPN | 3251 | 3251 | 523623 |

| FMI | 4 | 3 | 3 | |

| MIL | ON | ON | ON | |

| Detected Item | • Ground short circuit of sensor or harness | • Open circuit or +B short circuit of sensor or harness | • +B short of lamp driving circuit when lamp is ON | |

| DTC Set Preconditions | • Battery voltage is normal • Sensor supply voltage VCC# is normal • Starter switch signal (ECU: V12 terminal) is not activated |

• Battery voltage is normal • Sensor supply voltage VCC# is normal • Starter switch signal (ECU: V12 terminal) is not activated |

• Battery voltage is normal • Starter switch signal (ECU: V12 terminal) is not activated • Active regeneration lamp is ON |

|

| DTC Set Conditions | • DPF differential pressure sensor voltage: 0.21 V or less | • DPF differential pressure sensor voltage: 4.7 V or more | • +B short circuit | |

| Period for Judgment or Number of Occurrence for Judgment | • 2.8 sec or more | • 2.8 sec or more | • 2 sec or more | |

| System Action | • 0 kPa (0.0 kg/cm2, 0.0 psi) [default value] • Output limitation: Approximately 75% of normal condition |

• 0 kPa (0.0 kg/cm2, 0.0 psi) [default value] • Output limitation: Approximately 75% of normal condition |

• | |

| Engine Warning Light | ON | ON | ON | |

| DTC Fault Code | P 2621 | P 2622 | P 3001 | |

|---|---|---|---|---|

| Name | Intake throttle lift sensor: Low | Intake throttle lift sensor: High | Aftertreatment 1 Exhaust Gas Temperature 2 Preliminary FMI | |

| DTC Name | Intake throttle lift sensor: Low | Intake throttle lift sensor: High | Emission deterioration | |

| J1939 | SPN | 523582 | 523582 | 3252 |

| FMI | 4 | 3 | 0 | |

| MIL | ON | ON | ON | |

| Detected Item | • Intake throttle lift sensor: Low | • Intake throttle lift sensor: High | • DOC is heated up due to unburned fuel |

|

| DTC Set Preconditions | • Battery voltage is normal • Sensor supply voltage VCC# is normal |

• Battery voltage is normal • Sensor supply voltage VCC# is normal |

• Other than during regeneration mode • Coolant temp. is 65 deg. C (149 deg. F) or more continues longer than 5min after engine starting |

|

| DTC Set Conditions | • Intake throttle lift sensor voltage: 0.1 V or less | • Intake throttle lift sensor voltage: 4.89 V or more | • T1 – T0 is 250 deg. C (482 deg. F) or more | |

| Period for Judgment or Number of Occurrence for Judgment | • 2.8 sec or more | • 2.8 sec or more | • 60 sec or more | |

| System Action | • Output limitation: Approximately 75% of normal condition • Intake throttle 100% open |

• Output limitation: Approximately 75% of normal condition • Intake throttle 100% open |

• Output limitation: Approximately 50% of normal condition. Speed limitation (Accelerator limitation: 50%). EGR stop Intake throttle 100% open | |

| Engine Warning Light | ON | ON | ON | |

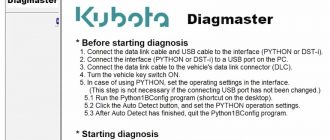

How To Reset Kubota Engine Error Codes?

You can often reset Kubota Engine Error Codes, but it’s essential to understand when and how to do it properly. Resetting error codes should only be done after you have identified and resolved the underlying issue that triggered the code. Here are the general steps to reset Kubota Engine Error Codes:

- Identify and Resolve the Issue: Use your engine’s user manual or diagnostic tool to determine the cause of the error code. Address the problem by fixing the issue, whether it’s related to fuel, air, electrical systems, or other components.

- Access the Diagnostic System: Depending on your Kubota engine model, you may need to use a diagnostic tool or display module to access the error code and reset it. Refer to your engine’s user manual for specific instructions on how to access the diagnostic system.

- Clear the Error Code: Once you’ve accessed the diagnostic system, locate the option to clear or reset error codes. Follow the on-screen or manual instructions to clear the code. This typically involves confirming that the issue has been resolved.

- Test the Engine: Before resuming regular operation, start the engine and run some tests to verify that the issue is indeed resolved and that the error code does not reappear.

- Monitor for Recurrence: Continue to monitor the engine for any recurrence of the error code. If the code reappears, it may indicate an ongoing or unresolved issue that requires further investigation and repair.

Remember that resetting error codes without addressing the root cause can lead to more significant problems. It’s essential to ensure that the issue has been properly fixed before clearing the code. If you’re unsure about the troubleshooting and reset process, or if the issue persists, it’s advisable to contact a Kubota-authorized service technician for assistance.

Kubota Engine Error Codes FAQ

Error codes serve as a diagnostic tool to help engine owners and technicians identify and address issues efficiently.

They are designed to streamline the troubleshooting process and pinpoint the root cause of a problem, saving time and reducing repair costs.

- Why are Kubota engine error codes important? Kubota engine error codes are essential for diagnosing engine problems quickly and accurately. They provide valuable information about the nature and location of faults, enabling technicians to troubleshoot efficiently.

- How do I interpret Kubota engine error codes? Each Kubota engine error code consists of a letter and a series of numbers. The letter indicates the system or component affected, while the numbers provide additional details about the specific fault or condition.

- What should I do if I encounter a Kubota engine error code? When a Kubota engine error code appears, it’s essential to refer to the manufacturer’s documentation or service manual to identify the code’s meaning and possible causes. Depending on the severity of the issue, you may need to address it immediately or schedule maintenance with a qualified technician.

- Can I reset Kubota engine error codes? In some cases, Kubota engine error codes can be cleared or reset by disconnecting the battery or using diagnostic tools compatible with Kubota engines. However, it’s crucial to diagnose and address the underlying issue before resetting error codes to prevent recurring problems.

- Are Kubota engine error codes universal across all models? While many Kubota engine error codes are standardized across various models, some codes may be specific to particular engine configurations or applications. Always consult the appropriate documentation for your specific Kubota engine model.

- How can I prevent Kubota engine error codes? Regular maintenance, including scheduled inspections, fluid checks, and component replacements, can help prevent many issues that trigger Kubota engine error codes. Following Kubota’s recommended maintenance schedule and operating guidelines is key to ensuring optimal engine performance and reliability.

- Are Kubota engine error codes covered under warranty? Warranty coverage for Kubota engine error codes depends on the terms and conditions of the warranty agreement. Typically, manufacturer warranties may cover certain repairs related to engine malfunctions indicated by error codes, but it’s essential to review the warranty documentation for specific coverage details.

- Can I diagnose Kubota engine error codes myself? While some Kubota engine error codes may be straightforward to diagnose, others may require specialized diagnostic tools and technical knowledge. If you’re experienced with engine troubleshooting and have access to the necessary tools and resources, you may be able to diagnose and address certain issues yourself. However, for complex or severe problems, it’s best to seek assistance from a qualified technician.

- What are some common causes of Kubota engine error codes? Common causes of Kubota engine error codes include fuel system issues, electrical problems, sensor malfunctions, cooling system faults, and mechanical failures. Environmental factors, improper maintenance, and operational errors can also contribute to error code generation.

- How can I find the meaning of a specific Kubota engine error code? To find the meaning of a specific Kubota engine error code, refer to the manufacturer’s documentation, service manuals, or online resources provided by Kubota dealerships or authorized service centers. These resources typically include comprehensive lists of error codes along with their descriptions and troubleshooting procedures.

- Can Kubota engine error codes be indicative of serious problems? While some Kubota engine error codes may indicate minor issues or temporary malfunctions, others may signal more serious problems that require immediate attention. Ignoring certain error codes or neglecting necessary repairs could lead to significant engine damage or performance degradation over time.

- Are there diagnostic tools available for troubleshooting Kubota engine error codes? Yes, Kubota dealerships and authorized service centers typically use diagnostic tools and equipment designed specifically for diagnosing engine faults and reading error codes. These tools allow technicians to perform comprehensive diagnostics and identify the root causes of engine problems quickly and accurately.

- Can Kubota engine error codes affect engine performance or fuel efficiency? Yes, unresolved Kubota engine error codes can negatively impact engine performance, fuel efficiency, and overall reliability. Ignition timing, fuel delivery, emissions control, and other critical engine functions may be affected by underlying issues indicated by error codes.

- Is it safe to continue operating the engine if an error code is present? It’s generally not advisable to continue operating the engine if an error code is present, especially if the code indicates a serious issue or potential safety hazard. Continuing to run the engine under such conditions could exacerbate the problem and lead to costly repairs or engine failure.

- How often should I check for Kubota engine error codes? Regularly monitoring for Kubota engine error codes as part of routine maintenance and inspection procedures can help detect and address issues early, minimizing the risk of more severe problems down the line. Depending on your operating conditions and usage, checking for error codes during scheduled service intervals or whenever unusual symptoms arise is recommended.

Hello, my Kubota L4060 compact tractor keeps displaying a P2414 code, what does that mean? Is this an Kubota engine problem?

OBD-II fault code P2414 mean = O2 Sensor Exhaust Sample Error (Oxygen sensor failure). If the Oxygen Sensor reads too much O2 at part or full throttle, the Kubota engine computer assumes that the O2 sensor is installed incorrectly or there is an exhaust leak – error code P2414 will be set. Sometimes this sensor can give an error due to overheating of the EGR valve.

TCU FMI 3 SPN 5110

The Kubota Error Code TCU FMI 3 SPN 5110 indicates a communication issue between the Transmission Control Unit (TCU) and the Engine Control Unit (ECU). Specifically, this error code is associated with a fault in the TCU’s ability to receive or send data correctly. SPN (Suspect Parameter Number) 5110: This number identifies the specific fault related to communication errors within the system (Controller #4). FMI (Failure Mode Identifier) 3: This indicates that there is a “signal below normal, or shorted to low voltage” condition. Essentially, it suggests that the signal being sent or received is not within the expected range, which can be due to wiring issues, sensor malfunctions, or other electrical problems.

I have a kubota KX057 that came up with a code eco ep syserr when i rehooked the battery. Didn’t have it before that what could it be?

Possible Causes: 1) Voltage Irregularities – a spike or dip in voltage when reconnecting the battery could trigger the error. Loose or corroded battery terminals might cause poor electrical contact. 2) Sensor or ECU Glitch – a. temporary fault in the Engine Control Unit (ECU) or associated sensors due to improper reconnection. Accidental grounding or shorting during battery installation. 3) Fault in the ECO Mode System – the “ECO” component of the error suggests an issue with the machine’s eco-friendly mode, which optimizes fuel efficiency and engine output. 4) System Calibration or Memory Reset Required – when the battery is disconnected, some systems may require recalibration or a reset.

I have a Kubota L3901 with the D1803-7HF engine I got a PO193 code and after testing the rail sensor a code PO087 came out also. What would be the correct way to trouble shoot this problem? The machine only has 60 hrs on it. Thank you

P0193 – Fuel Rail Pressure Sensor Circuit High Input. This means the ECU is detecting unusually high voltage from the fuel rail pressure sensor, which usually indicates:

– Faulty rail pressure sensor

– Wiring issues (short to voltage)

– Failing fuel pressure relief valve

– Fuel pressure truly too high (less likely, especially with only 60 hours)

P0087 – Fuel Rail/System Pressure Too Low. This points to low fuel pressure in the rail – often caused by:

– Clogged fuel filter

– Weak/failing low-pressure lift pump

– Failing high-pressure pump

– Faulty rail pressure sensor giving incorrect readings

1. Check Fuel Quality (Drain a sample from the tank and check for water, debris, or algae. If contaminated, flush and replace with fresh, clean diesel).

2. Inspect Fuel Filters (Replace the primary and secondary fuel filters. Even with only 60 hours, if the tractor was run with poor fuel, these could be clogged. Air in the fuel system after a filter change can also trigger low pressure codes, so bleed the system thoroughly).

3. Check the Rail Pressure Sensor and Wiring (Visually inspect the sensor on the fuel rail. Look for cracked connector / bent pins / chafed or oil-soaked wiring / corrosion).

4. Check for Air Leaks or Restrictions (Look over the fuel lines from the tank to the pump for cracks or loose fittings that could pull in air. Ensure fuel tank breather cap is not clogged — a vacuum in the tank could restrict flow).

5. Scan Live Data (If Possible) – Use a diagnostic tool to observe live fuel rail pressure readings during cranking and running. Low pressure during cranking = weak lift pump or air in the system. Erratic or too-high readings = likely a sensor issue

Replace the Rail Pressure Sensor (If in Doubt) – If wiring checks out and the problem persists, the sensor may be sending false signals. These sensors are relatively inexpensive and known to fail even early in some cases.