Dimensions

| Overall Width | 43.0 ft in (13.11 m) |

| Height of A-frame | 46.0 ft in (14.0 m) |

| Height of Boom Point Sheaves | 68.6 ft in (20.87 m) |

| Overall Length | 113.3 ft in (34.54 m) |

| Length of Boom | 67 ft in (20.4 m) |

| Effective Length of Dipper Handle | 35.1 ft in (10.9 m) |

| Overall Length of Dipper Handle | 47.0 ft in (14.3 m) |

Weights

These weights will vary slightly depending upon dipper and optional equipment selection. All specifications are based on a 73 yd3 (56 m3) dipper and standard 79 in (2007 mm) treads

| Max. Operating Weight | 3066000 lb (1390714 kg) |

| Operating Weight (with dipper and standard links) | 3047670 lb (1382400 kg) |

| Net Weight (domestic, without ballast or dipper) | 2202820 lb (999182 kg) |

| Ballast (furnished by customer) | 667150 lb (302614 kg) |

| GP Dipper Weight (73 yd3 / 56 m3) | 177700 lb (80603 kg) |

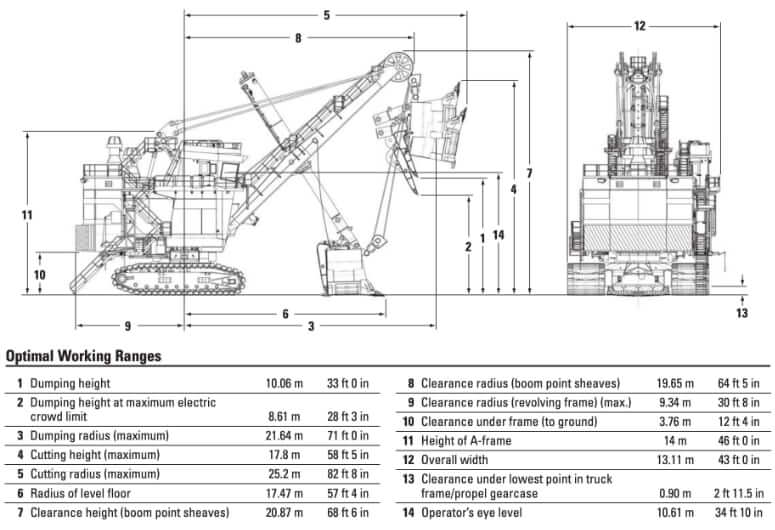

Working Ranges

Optimal working ranges based on loading a Cat 797F truck.

| Dipper Payload | 220000 lb (110000 kg) |

| Dipper Capacity | 40 – 80 yd3 (30.6 – 61.2 m3) |

| Maximum Dumping Height | 28.9 ft in (8.9 m) |

| Maximum Cutting Height | 53.5 ft in (16.4 m) |

| Maximum Cutting Radius | 80 ft in (24.4 m) |

| Radius Of Level Floor | 56.1 ft in (17.1 m) |

| Revolving Frame Tail Swing Radius | 30.5 ft in (9.3 m) |

Front End Boom

| Boom Type | Welded, impact-resistant steel boom |

| Boom Point Sheaves | Twin-grooved, flame-hardened |

| Point Sheave Diameters | 96 in (2438.4 mm) |

| Handle Diameter | 34 in (863.6 mm) |

| Wall Thickness (nominal) | 3 in (76.2 mm) |

Front End Rope Data

| Diameter | Construction | |

|---|---|---|

| Hoist (2 x twin dual) | 2.75 in (69.8 mm) | 8 × 37 |

| Boom Suspension (4 x equalized) | 3.25 in (82.6 mm) | struct. strand |

| Dipper Trip (1 x single) | 0.75 in (19.1 mm) | 7 × 25 |

Front End Crowd

| Rope Crowd Type | Rope Crowd, the crowd machinery is located at the front center of the revolving frame, consisting of motor, brake, drum and gearing. Plastic-coated crowd and retract ropes are used to move the dipper handle fore and aft. |

| Hydraulic Cylinder Bore Diameter | 14 in (356 mm) |

| Hydraulic Cylinder Rod Diameter | 10 in (254 mm) |

Lube System

| Lube System Type | Automatic, single-line system for open gear lubricant and grease. External FastFil from lower level |

| Lube System Pumps | 6 pumps (4 for open gear lubricant +2 for grease) located in an insulated, heated, double-walled lube room |

Electrical Power Requirements

Other voltage options available to suit customer requirements. Distribution System Requirements (machine on separate system) – 4000 kVA.

| Voltage | 3 phase, 50/60 Hz, 7,200 V |

| Nominal System Voltage | 50/60 Hz, 7,200V |

| Power Requirements (50 Hz) | 6,000 V, 6,600 V, 7,200 V, 11,000 V |

| Power Requirements (60 Hz) | 7,200 V, 13,800 V |

| Average Power Demand | 945-1322 kW |

| Peak Power | 3737 kW |

| Drive | IGBT Acutrol drive system |

| Trail Cable (furnished by customer) | SHD-3-#1/0 at 8,000 V |

| Transformer, Auxiliary | 350 kVA, 7,200V primary |

| Lighting transformer | 25 kVA, 120/240V secondary |

Main Structures

| Planetary Propel | Dual-motor independent drive |

| Crawler Mounting Overall Length | 37.6 ft in (11.43 m) |

| Crawler Mounting Overall Width (79″) Treads, Standard | 36 ft in (11.0 m) |

| Crawler Mounting Overall Width (102″) Treads | 44.3 ft in (13.5 m) |

| Total Effective Bearing Area (79″) Treads / Ground Pressure | 386.6 ft2 / 54.2 psi (36.1 m2 / 374 kPa) |

| Total Effective Bearing Area (102″) Treads / Ground Pressure | 501.7 ft2 / 50.0 psi (46.6 m2 / 289 kPa) |

| Number and Diameter of Lower Rollers | 16 x 30.7 in (78 cm) |

| Number and Diameter of Lower Rear Rollers | 2 x 42 in (106.7 cm) |

| Take-up Tumblers Diameter | 63.8 in (162 cm) |

| Number and Pitch of Treads | 94 x 20 in (50.8 cm) |

CAT 7495 Swing – Two planetary gearboxes, each driven by a vertically mounted motor, are located on either side of the revolving frame. Dual-output pinion shafts from each gearbox engage the swing rack. CAT 7495 Hoist – A planetary gearbox with dual-output pinions provides the hoist torque transfer from the electric motor to the hoist drum gear.