In 2023, Agco unveiled its latest innovation, the Massey Ferguson 500R Series sprayer, engineered for affordability and user-friendliness. This adaptable sprayer comes in three variants: the MF 525R, boasting a 740-gallon (2800 L) capacity and 212 horsepower (158 kilowatts), MF 530R, with an 790-gallon (3000 L) tank and 235 HP (175 kW), and the MF 535R, with an 925-gallon (3500 L) tank and 235 HP (175 kW).

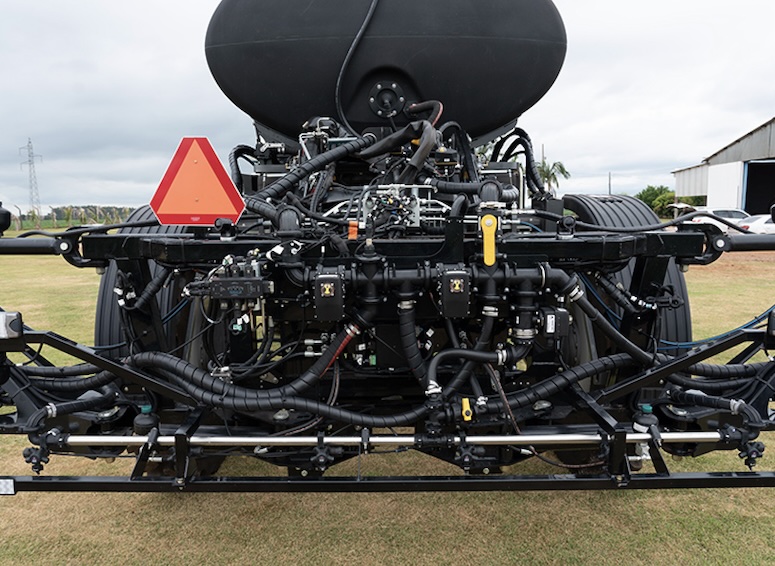

Enhanced with a modified carbon steel chassis featuring a non-welded frame, it ensures superior agility and traction across diverse field conditions. The MF 500R Series sprayer will make its inaugural appearance in North America at the 2023 Farm Progress Show, slated for August 29-31, 2023, in Decatur, Illinois.

Sporting the spacious cab design synonymous with Massey Ferguson’s esteemed S Series tractor, the sprayer offers noise and vibration reduction, ergonomic seating and controls, and nearly 360-degree visibility. Powered by a 7.4-liter Agco Power engine, it boasts smart all-wheel drive for optimized power-to-ground transfer, maintaining pump pressure at lower engine speeds to enhance fuel efficiency.

Inspired by Massey Ferguson S-Series tractors, the 500R’s cab design prioritizes comfort while minimizing noise and vibration. Operators benefit from an almost 360-degree view, allowing effortless monitoring of both tires and spray booms.

Massey Ferguson 500R Specs (MF 525R, 530R, 535R)

Here are the key specifications of the Massey Ferguson 500R Series Sprayers (MF 525R, MF 530R, MF 535R):

| Engine | |

|---|---|

| Engine Model | AGCO Power 66CW3.1263 MAR 1, Turbocharged |

| Displacement | 6.6 L |

| Max Power @ 1900 J ISO |

MF 525R – 212 HP (155 kW) MF 530R – 235 HP (172 kW) MF 535R – 235 HP (172 kW) |

| No of Cylinder | 6 |

| Aspiration | Turbocharged |

| Transmission | |

| Transmission Type | Hydrostatic independent 4WD |

| Pump | One piston pump |

| Wheel Motors | Axial with independent PWM |

| Max. Speed (Spraying) | 32 km/h (R46”) |

| Max. Speed (Transport) | 45 km/h (R46”) |

| Brake Service | Dynamic hydrostatic + pedal |

| Brake Parking | Electro-hydraulic disc |

| Chassis | Flex-frame |

| Material | Alloy steel |

| Shape | “C” section |

| Suspension Type | Independent active air with stabilizer bars |

| Track Width | Adjustment Hydraulic |

| Minimum | 2.8 m |

| Maximum | 3.4 m |

| Steering | Hydraulics |

| Turning radius | Meters 9.2 |

| Electrical System | |

| Battery | 1 of 170A |

| Voltage | 12V |

| Alternator | 200 A |

| 500R Cab | |

| Glazed area | 5.7 m2 |

| Suspension | 4 airbag suspension |

| Radio | Ready + Speakers |

| Air conditioning | Hot / Cold |

| Filters | 1 activated charcoal filter |

| Steering wheel | With height and depth adjustment |

| Operator’s seat | Pneumatic |

| Instructor’s seat | Standard |

| Compressed air outlet | Standard |

| Telescoping ladders | Automatic |

| Lighting | 8 LED roof lights + 2 blue LED for the booms |

| Capacities | |

| Fuel Tank Capacity | 350 L |

| Dimensions & Weights | |

| Overall length | 8.5 m |

| Overall height | 4.0 m |

| Minimum width | 3.2 m |

| Wheelbase | 4.4 m |

| Ground clearance (under the axle) | 1.65 m (R46) |

| Empty weight | 10,320 kg |

| Massey Ferguson 500R Tires | |

| Specification | 380/90R46 |

| Commodity Tank | |

| Tank Material | Polyethylene |

| Front Reloading Pump | 2 e 3” |

| Tank Capacity | MF 525R – 2800 L (740 gal) MF 530R – 3000 L (790 gal) MF 535R – 3500 L (925 gal) |

| Tank Flushing | Polyethylene |

| Agitator | 2 hydraulic agitators with proportional control |

| LiquidLogic package | Optional |

| Embedded Technology | |

| Guidance | MF Guide |

| Receivers | Trimble |

| Autosteer | Rangepoint / Centrepoint (optional) |

| Telemetry | MF Connect |

| Front Reloading Pump | |

| Type | Centrifugal |

| Make | Hypro |

| Material | Polypropylene |

| Clean Water Tank | |

| Capacity | 350 L + 40 L |

| Material | Polyethylene |

| Booms | |

| Assembly | Rear |

| Boom Width | MF 525R – 27 m MF 530R – 30 m MF 535R – 36 m |

| Min boom height | 32 cm or 73 cm |

| Max boom height | 218 cm or 259 cm |

| Lines | Stainless steel 1” |

| Nozzle body | 5 |

| Nozzle spacing | 50 cm |

| Number of sections | 9 or 36 (Optional) |

| Engagement | 3 Electro-pneumatic or Electric 2 |

| Sprayer Pump | |

| Make / Type | Hypro / Centrifugal |

| Engagement | Hydraulic motor |

| Maximum flow | 549 L/min |

| Material | Stainless steel |

| Reloading Station | |

| Lighting | Standard |

| Reloading system | Standard |

| Front reloading | Standard |

| Air outlet with quick release | Standard |

| Chemical Hopper | |

| Material | Polyethylene |

| Pump independent of spray system | Standard |

| Static capacity | 26.5 L |

| Sprayer System Filters | |

| Main filter | 30 mesh |

| Line filter | 80 mesh |

| Cameras | Optional |

* The color (🔶) indicates specs that differ between models of the 500R series.

This table provides a detailed comparison between the Massey Ferguson MF 525R, 530R and 535R models across various specifications.

Massey Ferguson 500R Sprayer Tank Size

| Specifications | MF 525R | MF 530R | MF 535R |

|---|---|---|---|

| Tank Material | Polyethylene | Polyethylene | Polyethylene |

| Tank Capacity | 2800 L (740 gal) | 3000 L (790 gal) | 3500 L (925 gal) |

| Tank Flushing | Polyethylene | Polyethylene | Polyethylene |

| Agitator | 2 hydraulic agitators with proportional control | 2 hydraulic agitators with proportional control | 2 hydraulic agitators with proportional control |

| LiquidLogic package | Optional | Optional | Optional |

| Front Reloading Pump | |||

| Type | Centrifugal 2 e 3” | Centrifugal 2 e 3” | Centrifugal 2 e 3” |

| Make | Hypro | Hypro | Hypro |

| Material | Polypropylene | Polypropylene | Polypropylene |

| Clean Water Tank | |||

| Capacity | 350 L + 40 L | 350 L + 40 L | 350 L + 40 L |

| Material | Polyethylene | Polyethylene | Polyethylene |

The sprayer’s standard LiquidLogic system primes in just 50 seconds, minimizing waste, while its 36 controllable boom sections ensure precise application, further reducing inefficiencies. An advanced recirculation system maintains a uniform mixture by consistently moving liquid through the tank and boom. Notably, the LiquidLogic system requires 75% less cleaning time and includes boom recovery and cleanout features.

“Massey Ferguson keeps the farmer at the heart of everything we do,” remarks Darren Parker, vice president of Massey Ferguson North America. “Farmers need a robust, entry-level spraying solution that provides fast ROI and a low total cost of ownership.

The MF 500R Series Sprayer gives producers the flexibility to apply product at the peak window for their particular crop, maximizing yields and positively impacting their bottom line.”

Massey Ferguson 500R PROs & CONs

Like any equipment, MF 525R, MF 530R and MF 535R sprayers come with their own set of advantages and limitations.

Here are the key pros and cons of the Massey Ferguson 500R Series sprayers for farmers looking to optimize their operations and maximize their yields.

MF 500R Sprayers PROs

- Precision Application: The sprayers offer precise application of chemicals or fertilizers, thanks to features like adjustable boom heights, controllable boom sections, and nozzle configurations. This precision helps in optimizing crop yield and reducing wastage.

- Customizability: With 3 models available (MF 525R, MF 530R and 535R) and various optional features, farmers can customize the sprayers according to their specific needs and field conditions, enhancing versatility and efficiency.

- Advanced Technology: Equipped with advanced technology such as GPS guidance, auto-steer, and the LiquidLogic® system, these sprayers improve accuracy, reduce overlaps, and minimize chemical wastage, resulting in cost savings and environmental sustainability.

- Comfort and Convenience: The cab design, inspired by Massey Ferguson’s S Series tractors, prioritizes operator comfort with ergonomic seating, controls, and almost 360-degree visibility, reducing operator fatigue during long hours of operation.

- Reliability and Durability: Built with high-quality materials and robust construction, the MF 500R Series sprayers offer reliability and longevity, ensuring uninterrupted operation even in demanding agricultural environments.

MF 500R Sprayers CONs

- High Initial Cost: The initial investment required for purchasing the Massey Ferguson 500R Series Sprayers may be higher compared to some alternatives. This could pose a challenge for farmers with budget constraints or those looking for a more affordable option.

- Complexity: While the advanced technology and features enhance performance, they may also add complexity to operation and maintenance. Farmers may require training or additional support to fully utilize and maintain these sprayers effectively.

- Maintenance Requirements: Like any agricultural equipment, the MF 500R Series sprayers require regular maintenance to ensure optimal performance and longevity. This may involve scheduled inspections, cleaning, and servicing, which can add to operational costs and downtime.

- Limited Availability: Depending on the region, dealerships, and distribution networks, the availability of Massey Ferguson 500R Series Sprayers may be limited. This could potentially pose challenges for farmers in accessing these sprayers or obtaining timely support and spare parts.

Overall, while the Massey Ferguson 500R Series Sprayers offer numerous benefits such as precision, customizability, and advanced technology, farmers need to consider factors like cost, complexity, maintenance, and availability before making a purchase decision.